Types Of Control Charts

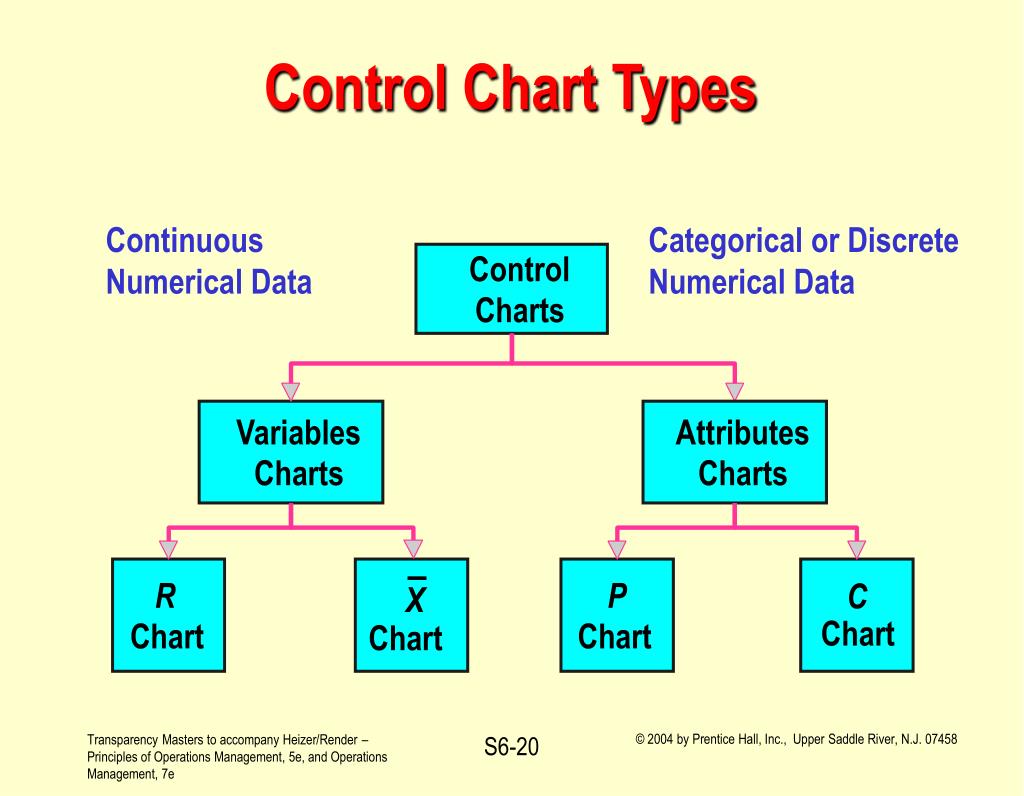

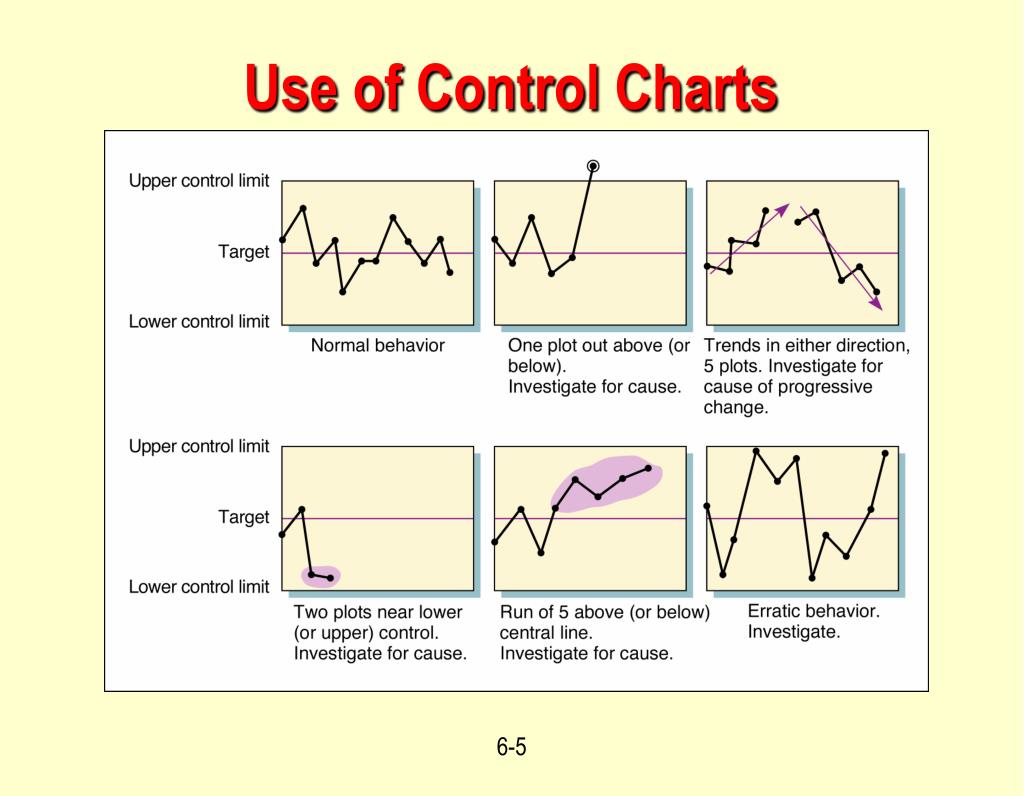

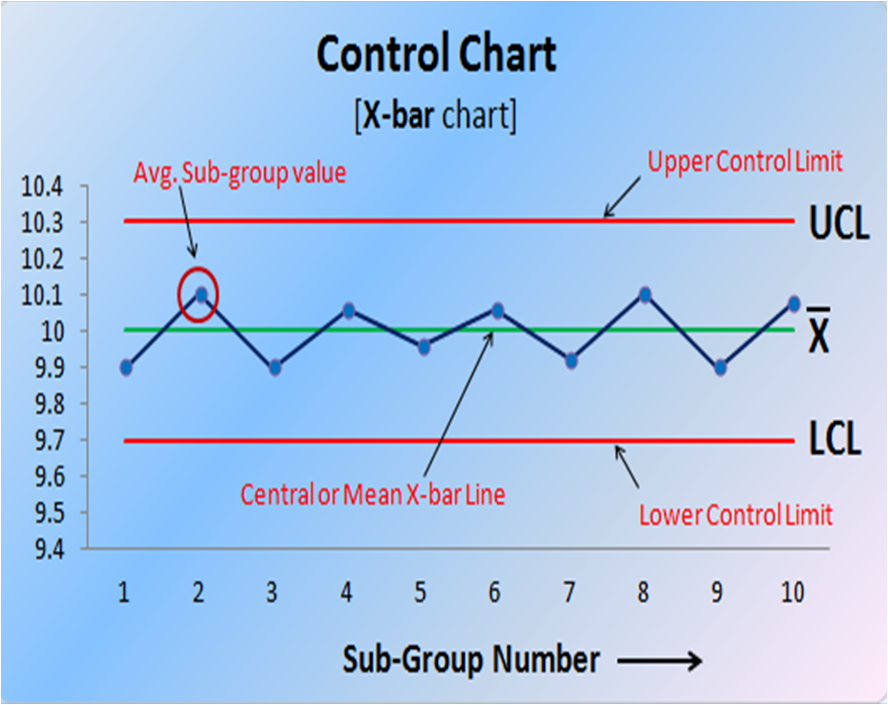

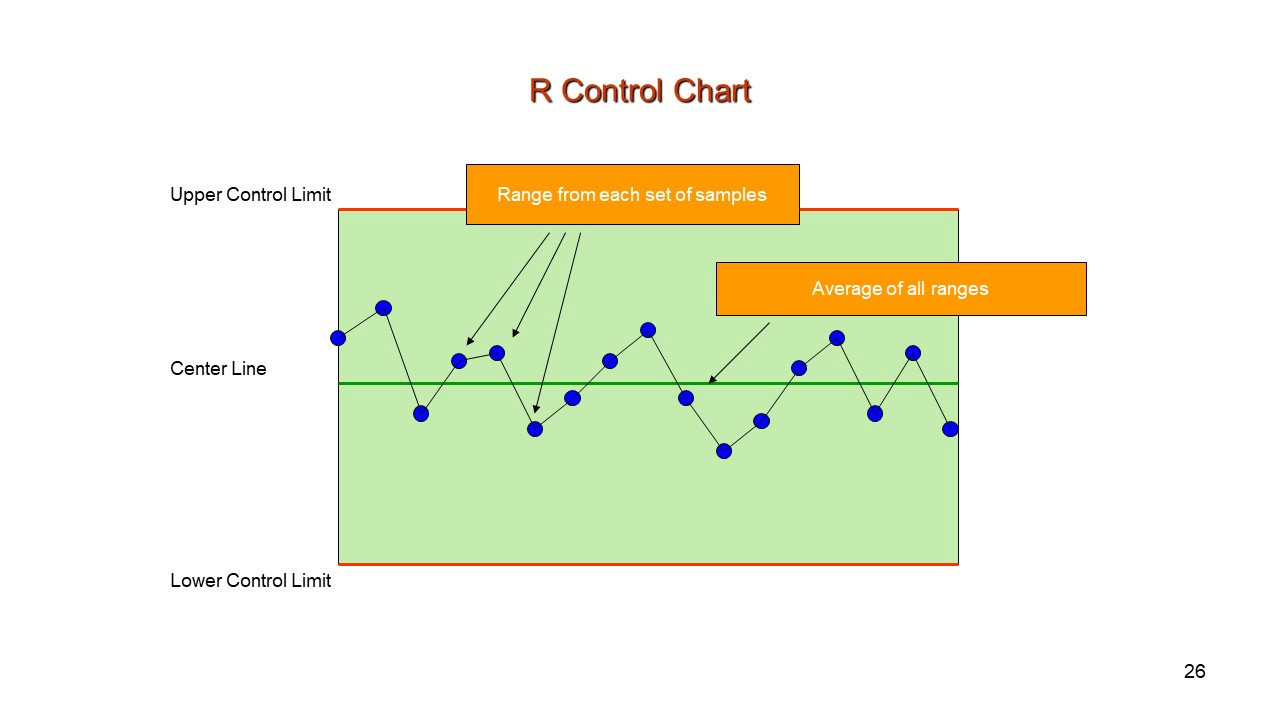

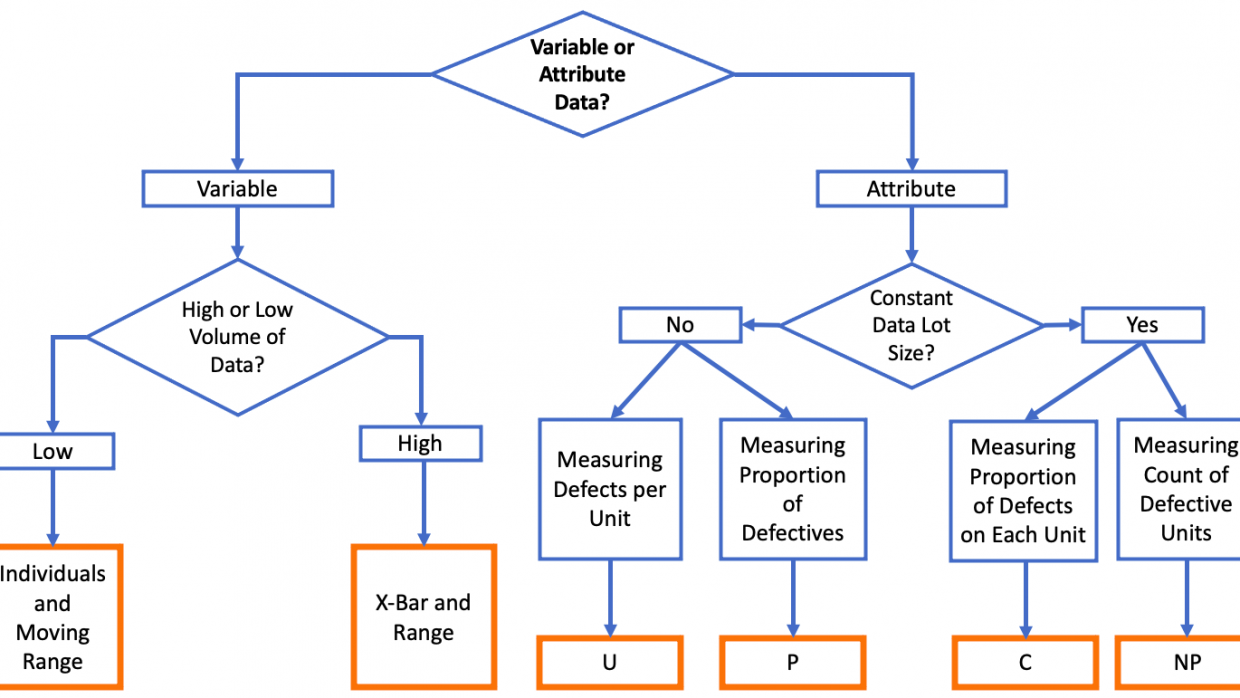

Types Of Control Charts - So in this chart you see, the chart is categorized based on data type,. A control chart is a graph which displays all the process data in order sequence. The control charts are broadly categorized into two types based on the nature of the data: Control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. Users can employ this chart type to gather and plot individual data points over time. Data points representing process outcomes. What is a control chart? There are two major types of control charts, which are further divided into subcategories, for better understanding the causes, controlling the process, and making it. Control charts typically contain the following elements: Control charts come in different types, each suited for monitoring a particular aspect of the process. So in this chart you see, the chart is categorized based on data type,. Control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. Users can employ this chart type to gather and plot individual data points over time. Data points representing process outcomes. The control charts are broadly categorized into two types based on the nature of the data: Our guide can help you identify which works best for your needs. These charts are used when the data being monitored is continuous. Control charts are indispensable in the toolkit of quality control, providing a systematic and visual approach to monitoring process stability and identifying areas for improvement. Therefore in the below chart, you will see what type of control chart is used and where it is applicable. How do you know which control charts to use for an improvement project? The types of control charts are: Data points representing process outcomes. What is a control chart? Therefore in the below chart, you will see what type of control chart is used and where it is applicable. Control charts come in different types, each suited for monitoring a particular aspect of the process. There are two major types of control charts, which are further divided into subcategories, for better understanding the causes, controlling the process, and making it. They are suitable for tracking processes. Control charts come in different types, each suited for monitoring a particular aspect of the process. How do you know which control charts to use for an improvement project?. Control charts come in different types, each suited for monitoring a particular aspect of the process. So in this chart you see, the chart is categorized based on data type,. It consists of a centre line, the upper limit and lower limit. Users can employ this chart type to gather and plot individual data points over time. A control chart. So in this chart you see, the chart is categorized based on data type,. Therefore in the below chart, you will see what type of control chart is used and where it is applicable. They are suitable for tracking processes. Control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under. There are two major types of control charts, which are further divided into subcategories, for better understanding the causes, controlling the process, and making it. Control charts come in different types, each suited for monitoring a particular aspect of the process. Control limits depict the range of normal process variability. How do you know which control charts to use for. The types of control charts are: Control limits depict the range of normal process variability. Control charts typically contain the following elements: The control charts are broadly categorized into two types based on the nature of the data: It consists of a centre line, the upper limit and lower limit. Control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. Control limits depict the range of normal process variability. Data points representing process outcomes. What is a control chart? Users can employ this chart type to gather and plot individual data points over time. Control charts typically contain the following elements: These charts are used when the data being monitored is continuous. The control charts are broadly categorized into two types based on the nature of the data: The types of control charts are: Control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under. There are two major types of control charts, which are further divided into subcategories, for better understanding the causes, controlling the process, and making it. Data points representing process outcomes. A control chart is a graph which displays all the process data in order sequence. How do you know which control charts to use for an improvement project? These charts. These charts are used when the data being monitored is continuous. The control charts are broadly categorized into two types based on the nature of the data: So in this chart you see, the chart is categorized based on data type,. What is a control chart? Therefore in the below chart, you will see what type of control chart is. Centre line of a chart. Control charts typically contain the following elements: These charts are used when the data being monitored is continuous. It consists of a centre line, the upper limit and lower limit. A control chart is a graph which displays all the process data in order sequence. Control charts come in different types, each suited for monitoring a particular aspect of the process. So in this chart you see, the chart is categorized based on data type,. Control limits depict the range of normal process variability. Our guide can help you identify which works best for your needs. The three most commonly used control charts are: How do you know which control charts to use for an improvement project? Data points representing process outcomes. The types of control charts are: Control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. What is a control chart? Control charts are indispensable in the toolkit of quality control, providing a systematic and visual approach to monitoring process stability and identifying areas for improvement.What Is A Control Chart Types Of Control Chart Examples Riset

Types Of Control Charts And When To Use Them at Ronald Whitehurst blog

How Many Types Of Control Charts Design Talk

Types of Control Charts Information & Training Statistical Improvement.PresentationEZE

Types Of Control Charts 7 rules for properly interpreting control charts

Types Of Control Charts 7 rules for properly interpreting control charts

Types Of Control Charts 7 rules for properly interpreting control charts

Control Charts » Learn Lean Sigma

Types Of Control Charts And When To Use Them at Ronald Whitehurst blog

Types Of Control Charts 7 rules for properly interpreting control charts

There Are Two Major Types Of Control Charts, Which Are Further Divided Into Subcategories, For Better Understanding The Causes, Controlling The Process, And Making It.

They Are Suitable For Tracking Processes.

The Control Charts Are Broadly Categorized Into Two Types Based On The Nature Of The Data:

Therefore In The Below Chart, You Will See What Type Of Control Chart Is Used And Where It Is Applicable.

Related Post: