Six Sigma Control Charts

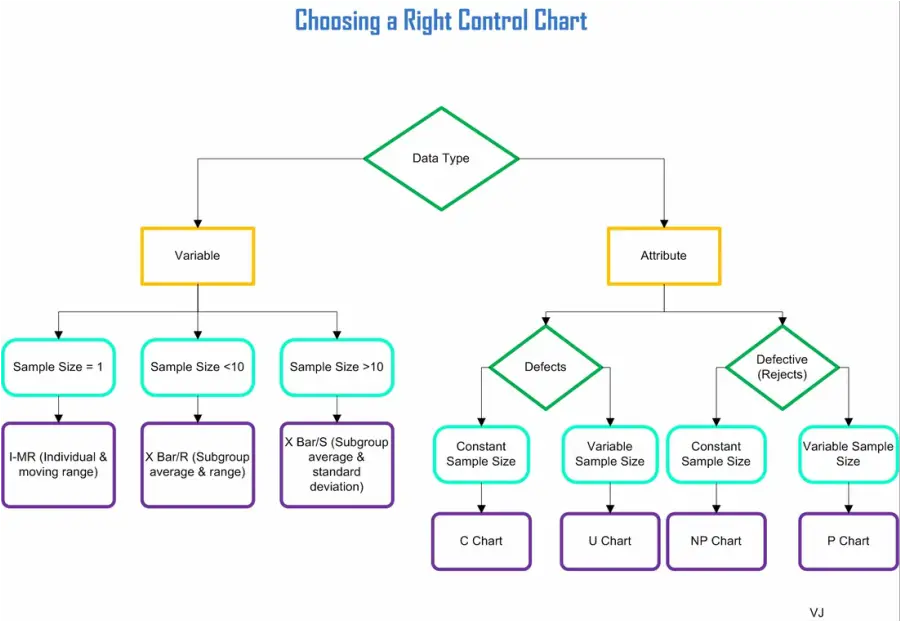

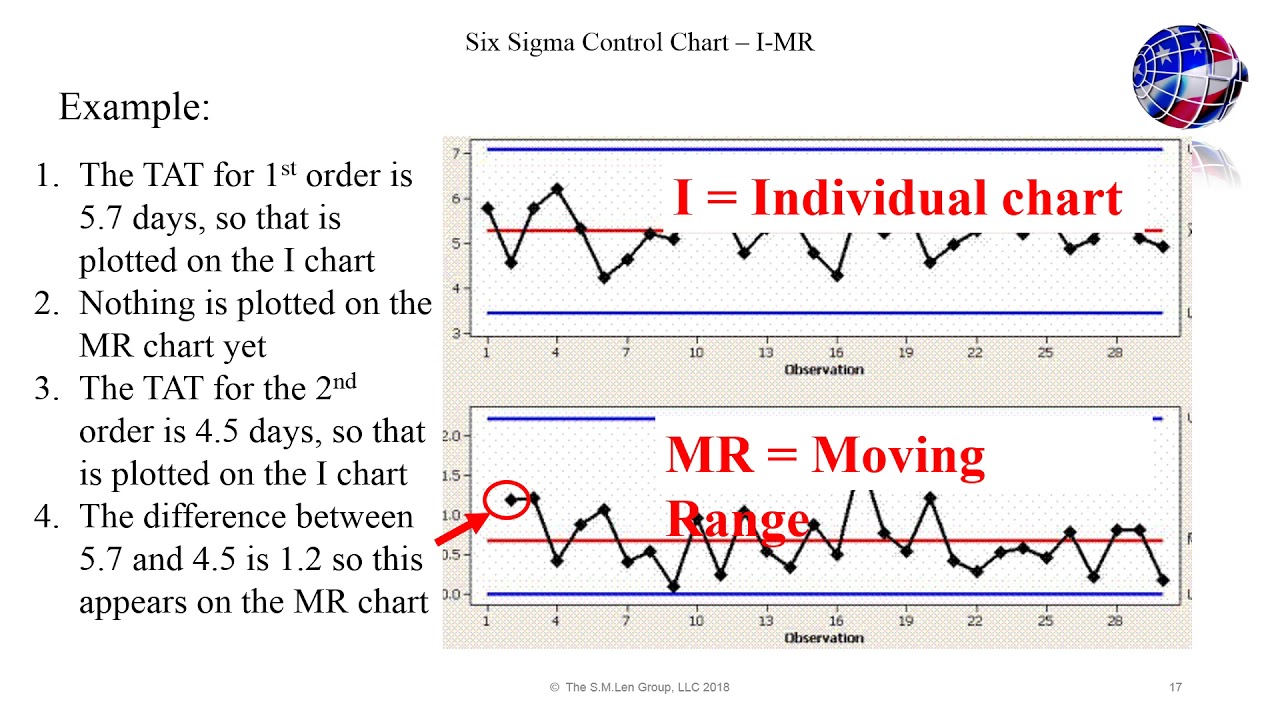

Six Sigma Control Charts - The charts help us track process statistics over time. Six sigma control charts are significant in monitoring and controlling process variation within the six sigma methodology. Control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. Creating a control chart requires a graph that covers a. How do you know which control charts to use for an improvement project? A six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. Control charts are time charts designed to display signals or warnings of special cause variation. Special cause variation, as distinct from common cause variation, refers to changes in process. They visually represent process performance over. In a six sigma project, we can use a control chart at the starting of the project as well as at the improve phase to implement some necessary improvement steps and adopt. Special cause variation, as distinct from common cause variation, refers to changes in process. Use a control chart to tell the difference between common cause and special cause variation in a new process, or use it to determine how much common cause variation. Control charts are crucial six sigma tools that help organizations monitor processes, identify variations, and drive improvements. Our guide can help you identify which works best for your needs. Six sigma control charts are significant in monitoring and controlling process variation within the six sigma methodology. Different types of control charts serve. In a six sigma project, we can use a control chart at the starting of the project as well as at the improve phase to implement some necessary improvement steps and adopt. A six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. Control charts are time charts designed to display signals or warnings of special cause variation. Creating a control chart requires a graph that covers a. Control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. Use a control chart to tell the difference between common cause and special cause variation in a new process, or use it to determine how much common cause variation. Creating a control chart requires a graph that covers a. In a six. A six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. The charts help us track process statistics over time. Control charts are time charts designed to display signals or warnings of special cause variation. They visually represent process performance over. Our guide can help you identify which works. They visually represent process performance over. Six sigma control charts are significant in monitoring and controlling process variation within the six sigma methodology. Our guide can help you identify which works best for your needs. Use a control chart to tell the difference between common cause and special cause variation in a new process, or use it to determine how. Six sigma control charts are significant in monitoring and controlling process variation within the six sigma methodology. The charts help us track process statistics over time. A six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. Special cause variation, as distinct from common cause variation, refers to changes. Our guide can help you identify which works best for your needs. A six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. How do you know which control charts to use for an improvement project? Use a control chart to tell the difference between common cause and special. Different types of control charts serve. Our guide can help you identify which works best for your needs. They visually represent process performance over. Control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. A six sigma control chart is a simple yet powerful tool for evaluating the stability of a process. Special cause variation, as distinct from common cause variation, refers to changes in process. Control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. A six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. Control charts are time charts designed. Control charts are time charts designed to display signals or warnings of special cause variation. Control charts are crucial six sigma tools that help organizations monitor processes, identify variations, and drive improvements. Six sigma control charts are significant in monitoring and controlling process variation within the six sigma methodology. The charts help us track process statistics over time. Special cause. Control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. Control charts are crucial six sigma tools that help organizations monitor processes, identify variations, and drive improvements. The charts help us track process statistics over time. Six sigma control charts are significant in monitoring and controlling process variation within the six sigma. Control charts are crucial six sigma tools that help organizations monitor processes, identify variations, and drive improvements. Our guide can help you identify which works best for your needs. The charts help us track process statistics over time. Special cause variation, as distinct from common cause variation, refers to changes in process. Control charts are time charts designed to display. The charts help us track process statistics over time. Control charts are crucial six sigma tools that help organizations monitor processes, identify variations, and drive improvements. A six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. In a six sigma project, we can use a control chart at the starting of the project as well as at the improve phase to implement some necessary improvement steps and adopt. Different types of control charts serve. Our guide can help you identify which works best for your needs. Control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. Special cause variation, as distinct from common cause variation, refers to changes in process. Creating a control chart requires a graph that covers a. How do you know which control charts to use for an improvement project? Control charts are time charts designed to display signals or warnings of special cause variation.What is Control Charts in Six Sigma and How to Create them?

6 Sigma Control Chart Introduction Toolkit from Leanscape

6 Sigma Control Chart Introduction Toolkit from Leanscape

What Is A Control Chart In Six Sigma at Oscar Godson blog

Six Sigma Green Belt Introduction to Control Charts

Choosing a Right Control Chart Lean Six Sigma Training Guide Copy

What Is A Control Chart In Six Sigma at Oscar Godson blog

What is Lean Six Sigma? A Complete Overview of Lean 6 Sigma

PPT Six Sigma PowerPoint Presentation, free download ID2485291

They Visually Represent Process Performance Over.

Use A Control Chart To Tell The Difference Between Common Cause And Special Cause Variation In A New Process, Or Use It To Determine How Much Common Cause Variation.

Six Sigma Control Charts Are Significant In Monitoring And Controlling Process Variation Within The Six Sigma Methodology.

Related Post: