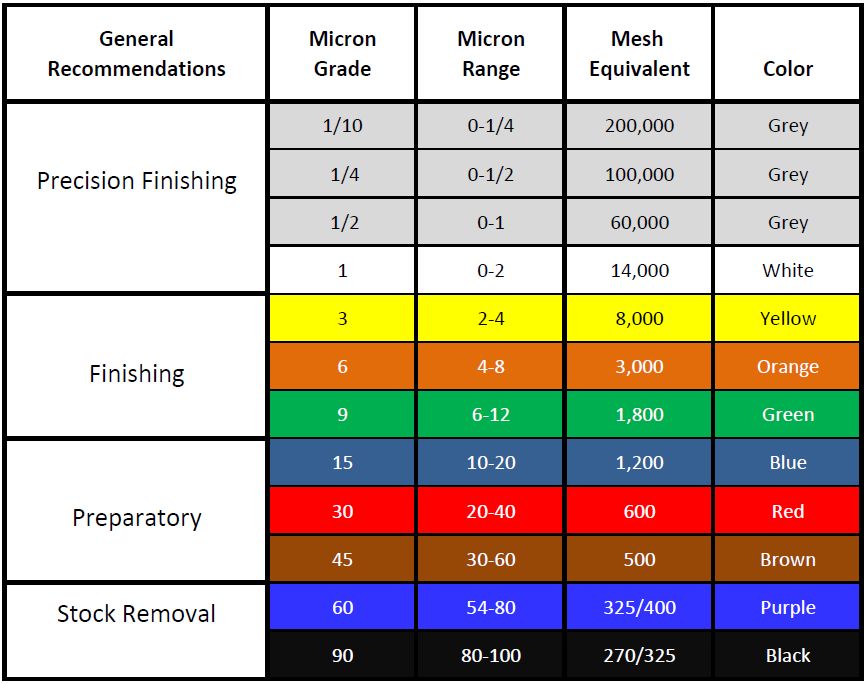

Polishing Compound Grit Chart

Polishing Compound Grit Chart - We’ll show you how to polish metal to remove discoloration, water stains, and tarnish. Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection (still limited by. It involves the removal of imperfections, such as scratches, oxidation, or roughness, by. The most common types of metal are steel, silver, aluminum, copper, iron, brass, and. Ever wondered how to achieve a flawless metal finish? Metal polishing has not only decorative value, but also serves a practical purpose. Polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. It assists in enhancing the appearance of the parts while preventing corrosion (by. It is commonly used to achieve a mirror finish or to improve corrosion. Polishing is a surface finishing process that smooths and enhances the texture of a material’s surface. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. Polishing helps protect surfaces from corrosion, oxidation, and environmental factors by creating a smoother, less porous surface that is easier to clean and maintain. Metal polishing has not only decorative value, but also serves a practical purpose. Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection (still limited by. It involves the removal of imperfections, such as scratches, oxidation, or roughness, by. Define and understand the basics of the polishing and how the process works and what functions each machine preforms. Ever wondered how to achieve a flawless metal finish? It is commonly used to achieve a mirror finish or to improve corrosion. Polishing is a finishing process that creates a smooth surface through different methods. This article dives into various polishing techniques, from mechanical to ultrasonic methods, detailing their. It involves the removal of imperfections, such as scratches, oxidation, or roughness, by. Define and understand the basics of the polishing and how the process works and what functions each machine preforms. It is commonly used to achieve a mirror finish or to improve corrosion. Polishing refers to the surface finishing process of refining and enhancing a surface by removing. We’ll show you how to polish metal to remove discoloration, water stains, and tarnish. Define and understand the basics of the polishing and how the process works and what functions each machine preforms. Polishing is a surface finishing process that smooths and enhances the texture of a material’s surface. Polishing is a finishing process that creates a smooth surface through. Metal polishing has not only decorative value, but also serves a practical purpose. Polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. Polishing helps protect surfaces from corrosion, oxidation, and environmental factors by creating a smoother, less porous surface that is easier to clean and. It assists in enhancing the appearance of the parts while preventing corrosion (by. Ever wondered how to achieve a flawless metal finish? It is commonly used to achieve a mirror finish or to improve corrosion. Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with. Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection (still limited by. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. The most common types of metal are steel, silver, aluminum,. We’ll show you how to polish metal to remove discoloration, water stains, and tarnish. Metal polishing has not only decorative value, but also serves a practical purpose. Ever wondered how to achieve a flawless metal finish? Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. Polishing helps protect surfaces from corrosion,. Polishing helps protect surfaces from corrosion, oxidation, and environmental factors by creating a smoother, less porous surface that is easier to clean and maintain. Polishing is a finishing process that creates a smooth surface through different methods. We’ll show you how to polish metal to remove discoloration, water stains, and tarnish. It assists in enhancing the appearance of the parts. Polishing is a surface finishing process that smooths and enhances the texture of a material’s surface. Define and understand the basics of the polishing and how the process works and what functions each machine preforms. Metal polishing has not only decorative value, but also serves a practical purpose. Polishing is a finishing process that creates a smooth surface through different. The most common types of metal are steel, silver, aluminum, copper, iron, brass, and. Define and understand the basics of the polishing and how the process works and what functions each machine preforms. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. Polishing is a surface finishing process that smooths and. It is commonly used to achieve a mirror finish or to improve corrosion. Polishing helps protect surfaces from corrosion, oxidation, and environmental factors by creating a smoother, less porous surface that is easier to clean and maintain. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. Polishing refers to the surface. We’ll show you how to polish metal to remove discoloration, water stains, and tarnish. Define and understand the basics of the polishing and how the process works and what functions each machine preforms. This article dives into various polishing techniques, from mechanical to ultrasonic methods, detailing their. It is commonly used to achieve a mirror finish or to improve corrosion. Metal polishing has not only decorative value, but also serves a practical purpose. Polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. Polishing helps protect surfaces from corrosion, oxidation, and environmental factors by creating a smoother, less porous surface that is easier to clean and maintain. It assists in enhancing the appearance of the parts while preventing corrosion (by. The most common types of metal are steel, silver, aluminum, copper, iron, brass, and. Polishing is a finishing process that creates a smooth surface through different methods. Ever wondered how to achieve a flawless metal finish? It involves the removal of imperfections, such as scratches, oxidation, or roughness, by.Polishing Compound Chart PDF Sets Of Chemical Elements Transition Metals

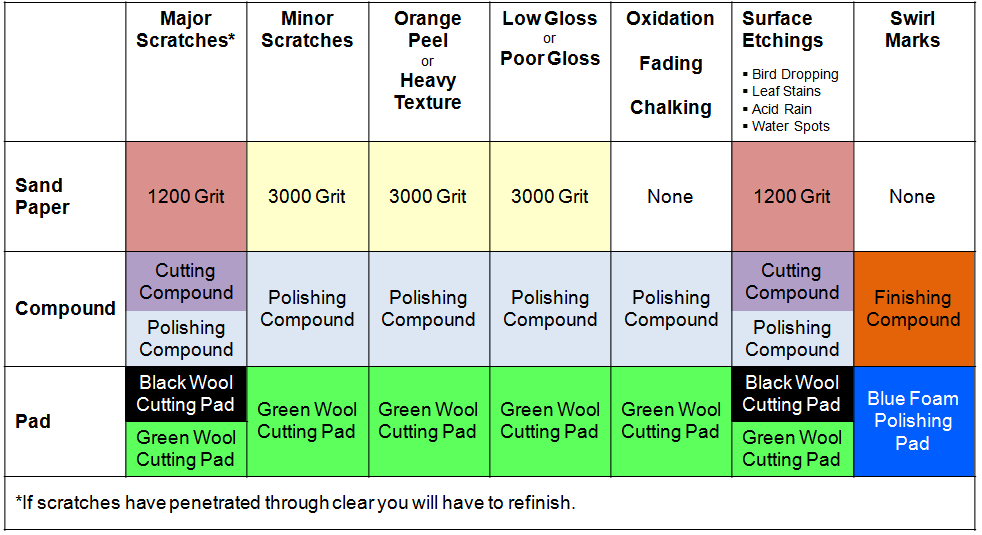

Rubbing Compound Grit Equivalent at Douglas Mcnew blog

Polishing & Detail Touch Up Zone

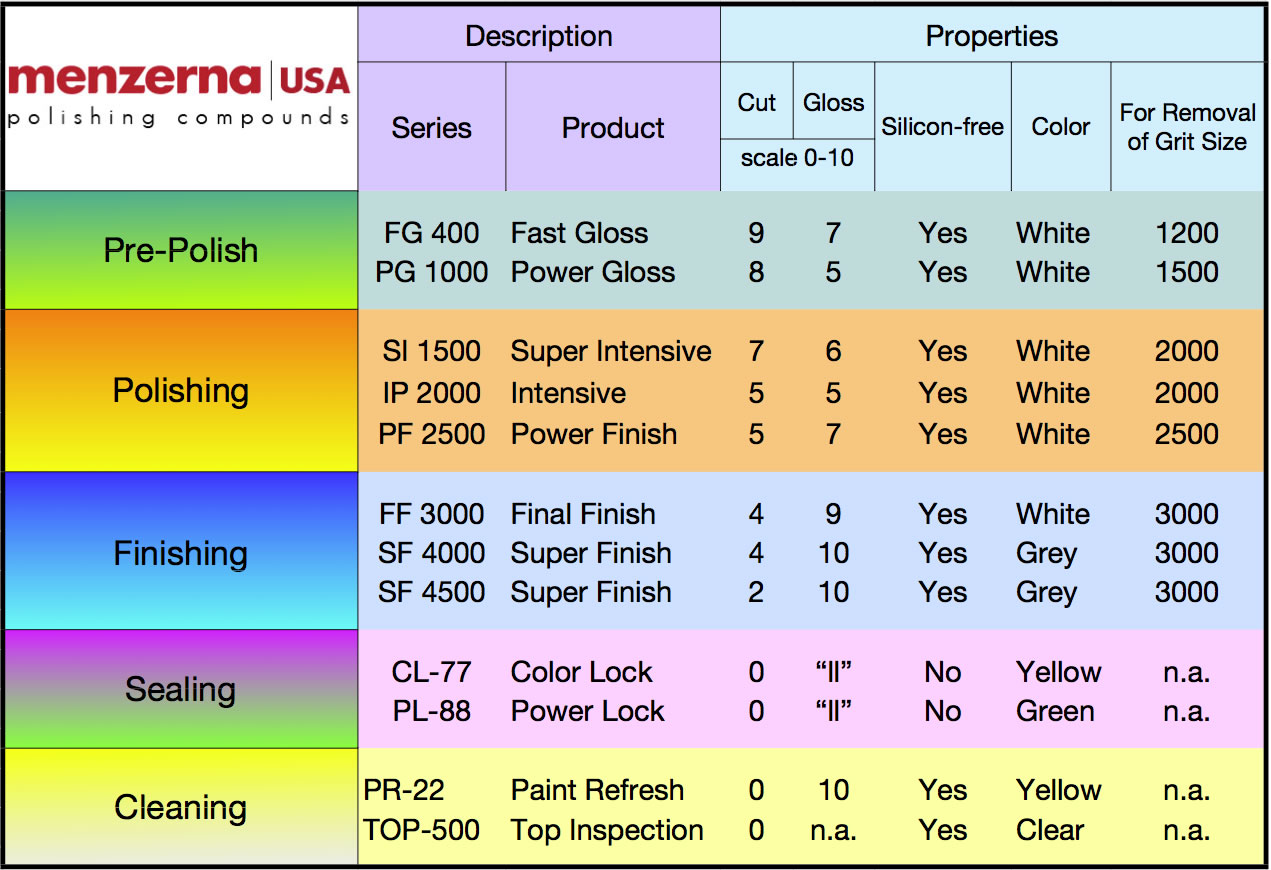

Menzerna Polishing Chart Detailed Image

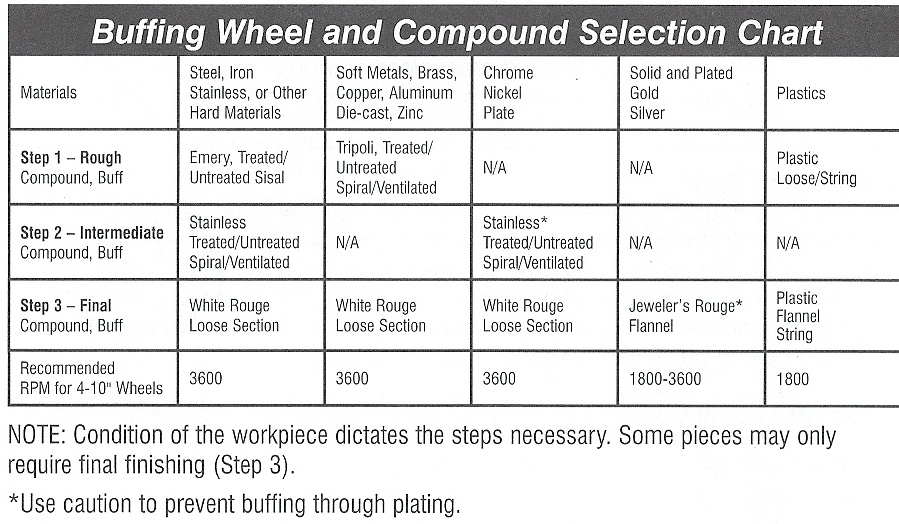

A Jeweler’s Guide to Using Polishing Compounds

Polishing Compound Grit Chart A Visual Reference of Charts Chart Master

Polishing Compound Grit Chart A Visual Reference of Charts Chart Master

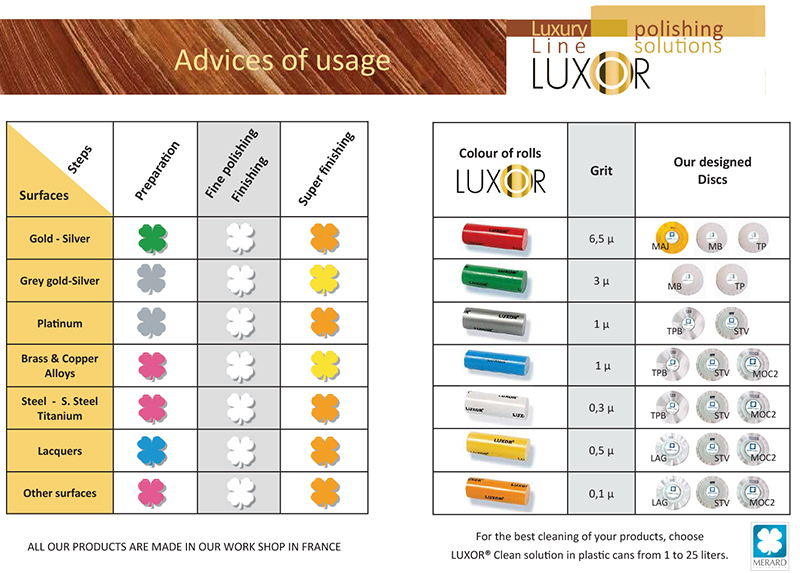

Luxor Polishing Compound Grey

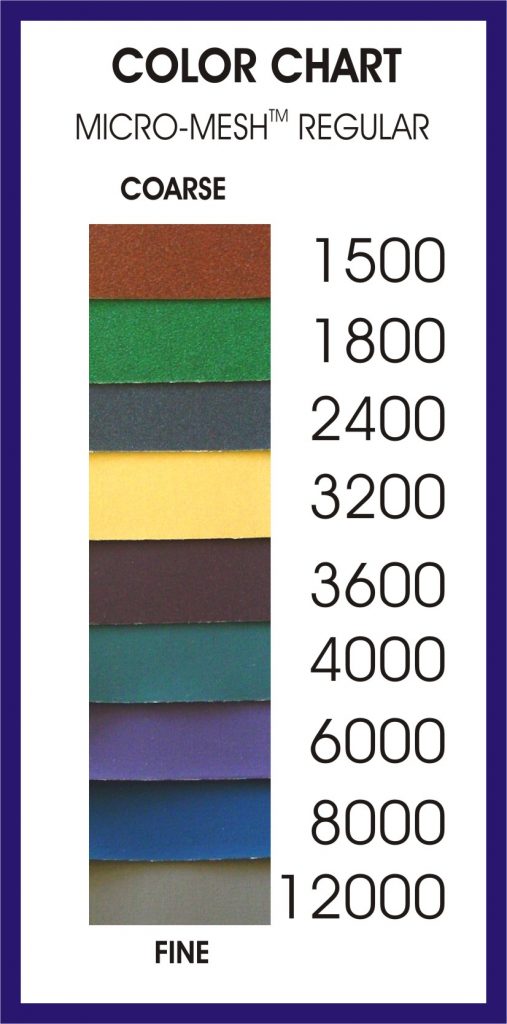

Grit Conversion Micro Surface

Polishing Compound Grit Chart Ponasa

Polishing Is The Process Of Creating A Smooth And Shiny Surface By Rubbing It Or By Applying A Chemical Treatment, Leaving A Clean Surface With A Significant Specular Reflection (Still Limited By.

Polishing Is A Surface Finishing Process That Smooths And Enhances The Texture Of A Material’s Surface.

Polishing Can Be Defined As The Process Of Refining A Surface To Achieve A Smooth And Lustrous Finish.

Related Post: