Galvanized Steel Compatibility Chart

Galvanized Steel Compatibility Chart - Galvanization (also spelled galvanisation) [1] is the process of applying a protective zinc coating to steel or iron, to prevent rusting. How to use galvanize in a sentence. Learn about its corrosion resistance, durability, key applications, and. This zinc coating forms a protective layer to stop the steel from rusting or. The material due to its weight. The galvanized protective coating protects the iron steel substrate from. Discover what galvanized steel is, how it’s made, and why it’s a top choice for industrial manufacturing. Galvanized steel is standard steel that is coated in zinc to provide enhanced corrosion resistance. Galvanized metal is ordinary steel covered with a protective zinc layer. Galvanized steel is the main type of steel used for building purposes, i.e in structural components such as trusses, beams and columns. Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. Galvanizing is a widely used industrial process designed to protect metal, particularly steel and iron, from corrosion. Galvanized steel is the main type of steel used for building purposes, i.e in structural components such as trusses, beams and columns. Discover what galvanized steel is, how it’s made, and why it’s a top choice for industrial manufacturing. This zinc coating forms a protective layer to stop the steel from rusting or. Galvanized steel comes in various types, developed to meet diverse applications, performance demands, and production constraints. The material due to its weight. This protective technique has been a cornerstone in. Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. There are several galvanizing processes. Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. Learn about its corrosion resistance, durability, key applications, and. The galvanized protective coating protects the iron steel substrate from. The meaning of galvanize is to subject to the action of an electric current especially for the. Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. Learn about its corrosion resistance, durability, key applications, and. There are several galvanizing processes. Galvanized steel is the main type of steel used for building purposes, i.e in structural components such as trusses, beams and columns.. There are several galvanizing processes. Discover what galvanized steel is, how it’s made, and why it’s a top choice for industrial manufacturing. This zinc coating forms a protective layer to stop the steel from rusting or. The meaning of galvanize is to subject to the action of an electric current especially for the purpose of stimulating physiologically. Learn about its. Galvanized steel is standard steel that is coated in zinc to provide enhanced corrosion resistance. Galvanized steel comes in various types, developed to meet diverse applications, performance demands, and production constraints. Learn about its corrosion resistance, durability, key applications, and. This zinc coating forms a protective layer to stop the steel from rusting or. Galvanizing is a widely used industrial. The galvanized protective coating protects the iron steel substrate from. The meaning of galvanize is to subject to the action of an electric current especially for the purpose of stimulating physiologically. How to use galvanize in a sentence. This zinc coating forms a protective layer to stop the steel from rusting or. Galvanizing, or galvanization, is a manufacturing process where. Galvanized steel comes in various types, developed to meet diverse applications, performance demands, and production constraints. The meaning of galvanize is to subject to the action of an electric current especially for the purpose of stimulating physiologically. There are several galvanizing processes. This zinc coating forms a protective layer to stop the steel from rusting or. Learn about its corrosion. There are several galvanizing processes. Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. The galvanized protective coating protects the iron steel substrate from. Galvanized steel is standard steel that is coated in zinc to provide enhanced corrosion resistance. Galvanizing, or galvanization, is a manufacturing. Galvanized metal is ordinary steel covered with a protective zinc layer. There are several galvanizing processes. Galvanized steel is the main type of steel used for building purposes, i.e in structural components such as trusses, beams and columns. Galvanizing is a widely used industrial process designed to protect metal, particularly steel and iron, from corrosion. Galvanized steel comes in various. Galvanization (also spelled galvanisation) [1] is the process of applying a protective zinc coating to steel or iron, to prevent rusting. This protective technique has been a cornerstone in. The galvanized protective coating protects the iron steel substrate from. Galvanized metal is ordinary steel covered with a protective zinc layer. Learn about its corrosion resistance, durability, key applications, and. Galvanized steel is the main type of steel used for building purposes, i.e in structural components such as trusses, beams and columns. There are several galvanizing processes. The meaning of galvanize is to subject to the action of an electric current especially for the purpose of stimulating physiologically. Galvanized steel is standard steel that is coated in zinc to provide. Learn about its corrosion resistance, durability, key applications, and. Galvanized steel is the main type of steel used for building purposes, i.e in structural components such as trusses, beams and columns. Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. How to use galvanize in a sentence. Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. The galvanized protective coating protects the iron steel substrate from. Galvanized metal is ordinary steel covered with a protective zinc layer. Galvanizing is a widely used industrial process designed to protect metal, particularly steel and iron, from corrosion. Galvanized steel comes in various types, developed to meet diverse applications, performance demands, and production constraints. This zinc coating forms a protective layer to stop the steel from rusting or. This protective technique has been a cornerstone in. There are several galvanizing processes. Galvanized steel is standard steel that is coated in zinc to provide enhanced corrosion resistance.Chemical Compatibility Chart For Galvanized Steel Pipes

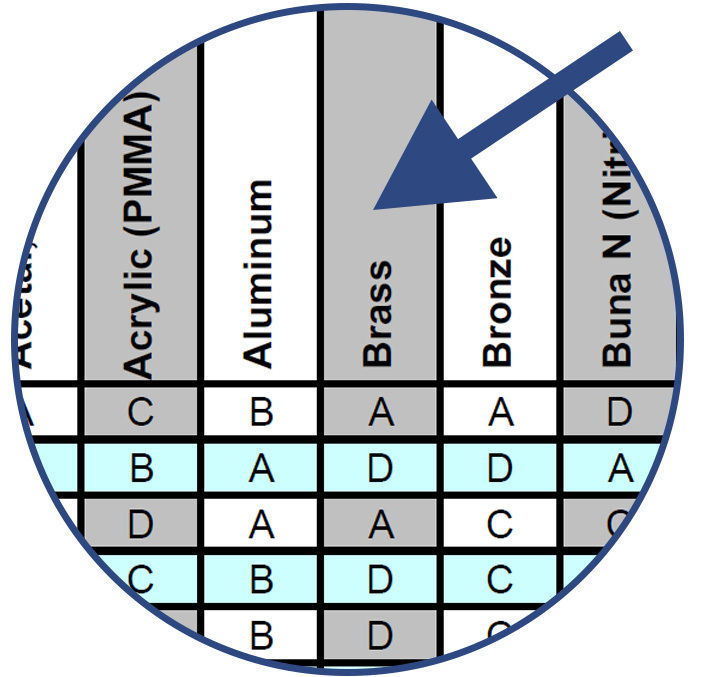

Galvanized Steel Compatibility Chart at Alyssa Reeks blog

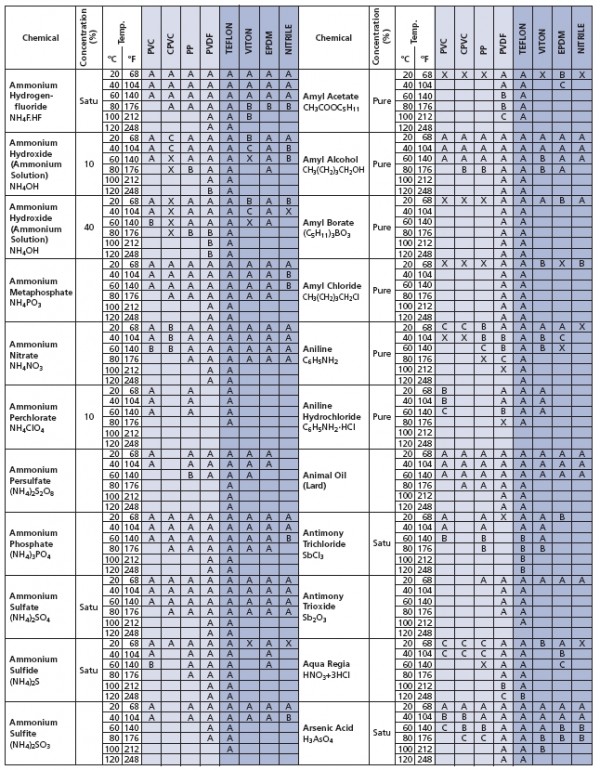

Chemical Compatibility Chart For Galvanized Steel

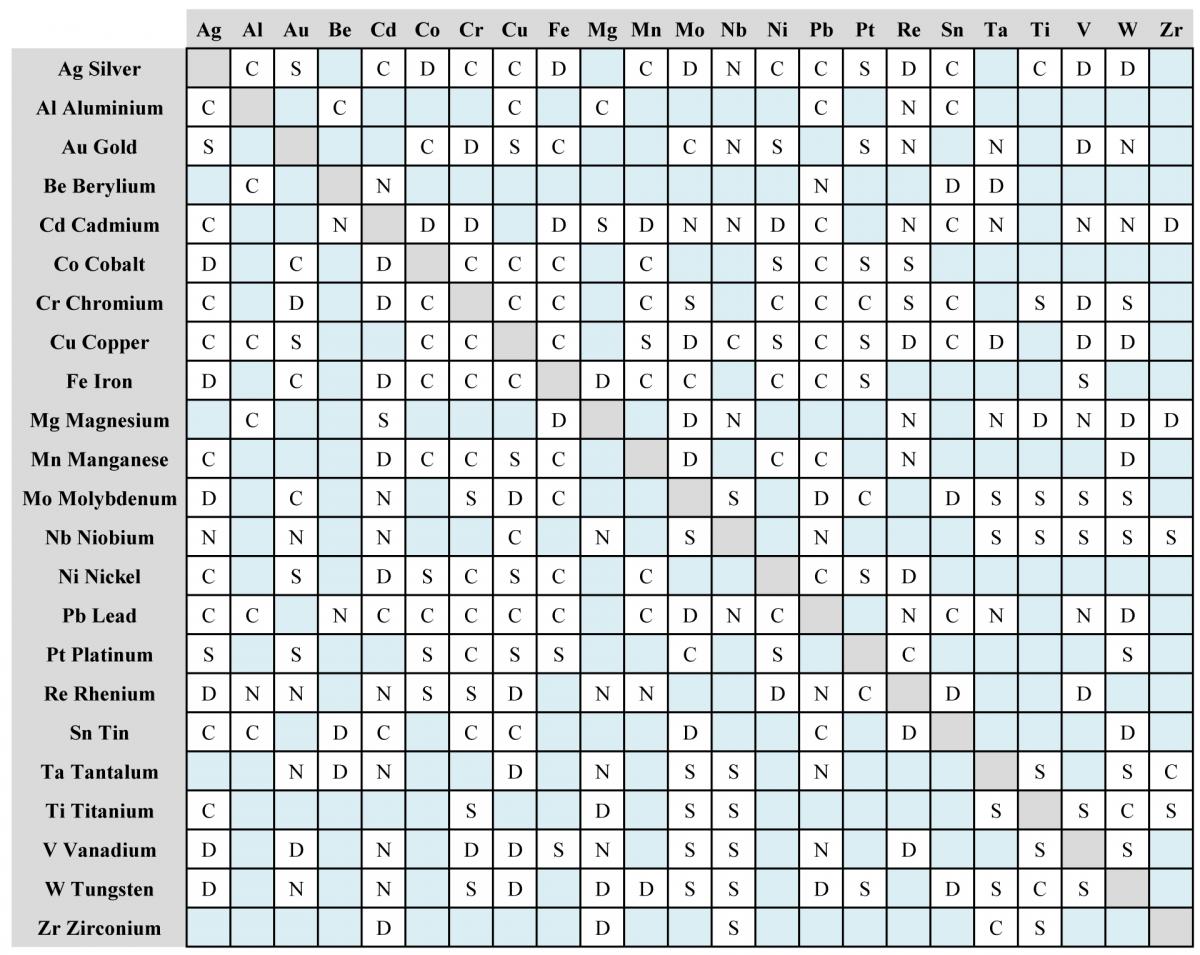

Copper Compatibility Chart A Visual Reference of Charts Chart Master

Chemical Compatibility Chart For Galvanized Steel And Copper

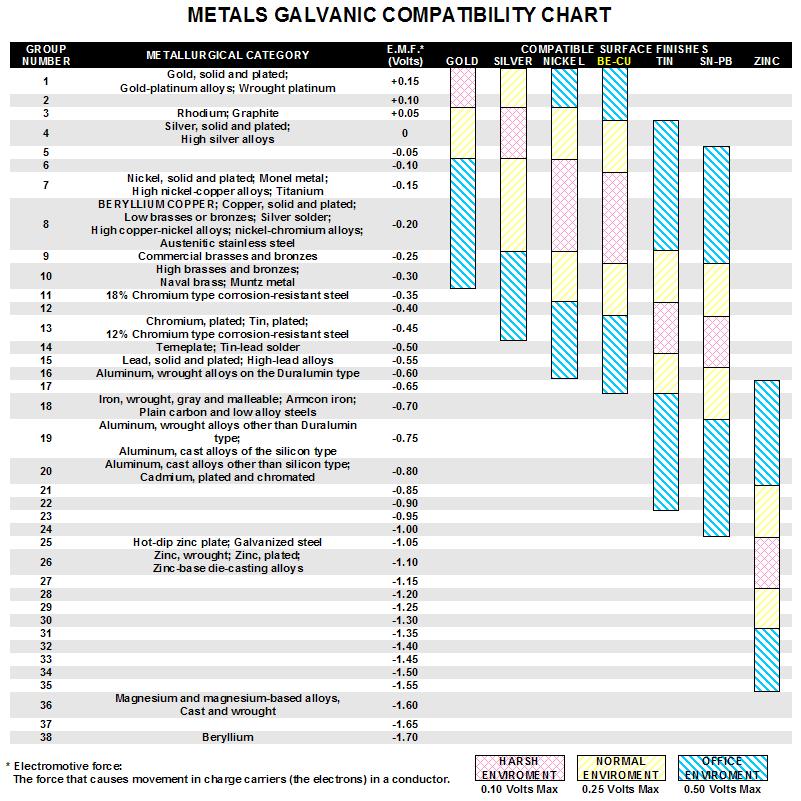

Metals Galvanic Compatibility Chart A Visual Reference of Charts Chart Master

Chemical Compatibility Chart For Galvanized Steel

Galvanized Steel Compatibility Chart at Alyssa Reeks blog

Metals Galvanic Compatibility Chart Leadertechinc

zinc and stainless steel reaction

Discover What Galvanized Steel Is, How It’s Made, And Why It’s A Top Choice For Industrial Manufacturing.

The Meaning Of Galvanize Is To Subject To The Action Of An Electric Current Especially For The Purpose Of Stimulating Physiologically.

The Material Due To Its Weight.

Galvanization (Also Spelled Galvanisation) [1] Is The Process Of Applying A Protective Zinc Coating To Steel Or Iron, To Prevent Rusting.

Related Post: