Fillet Weld Symbol Chart

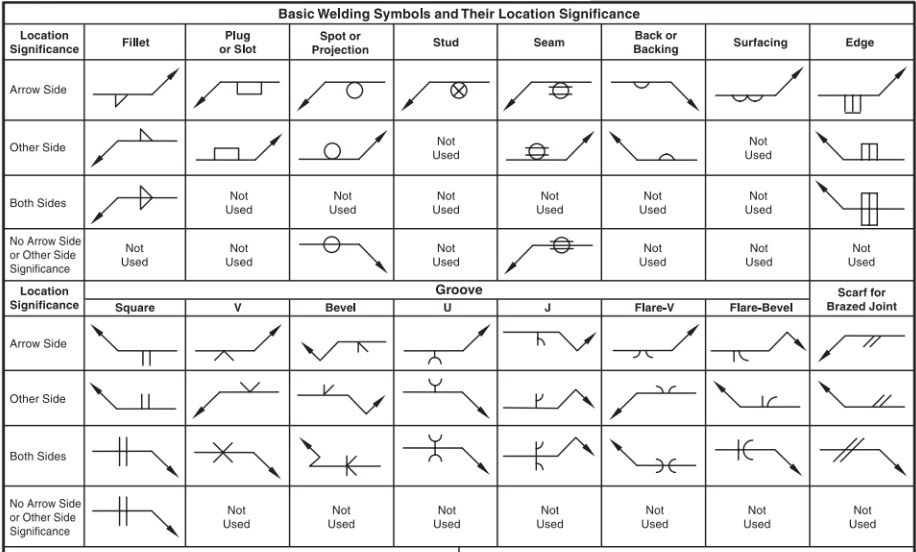

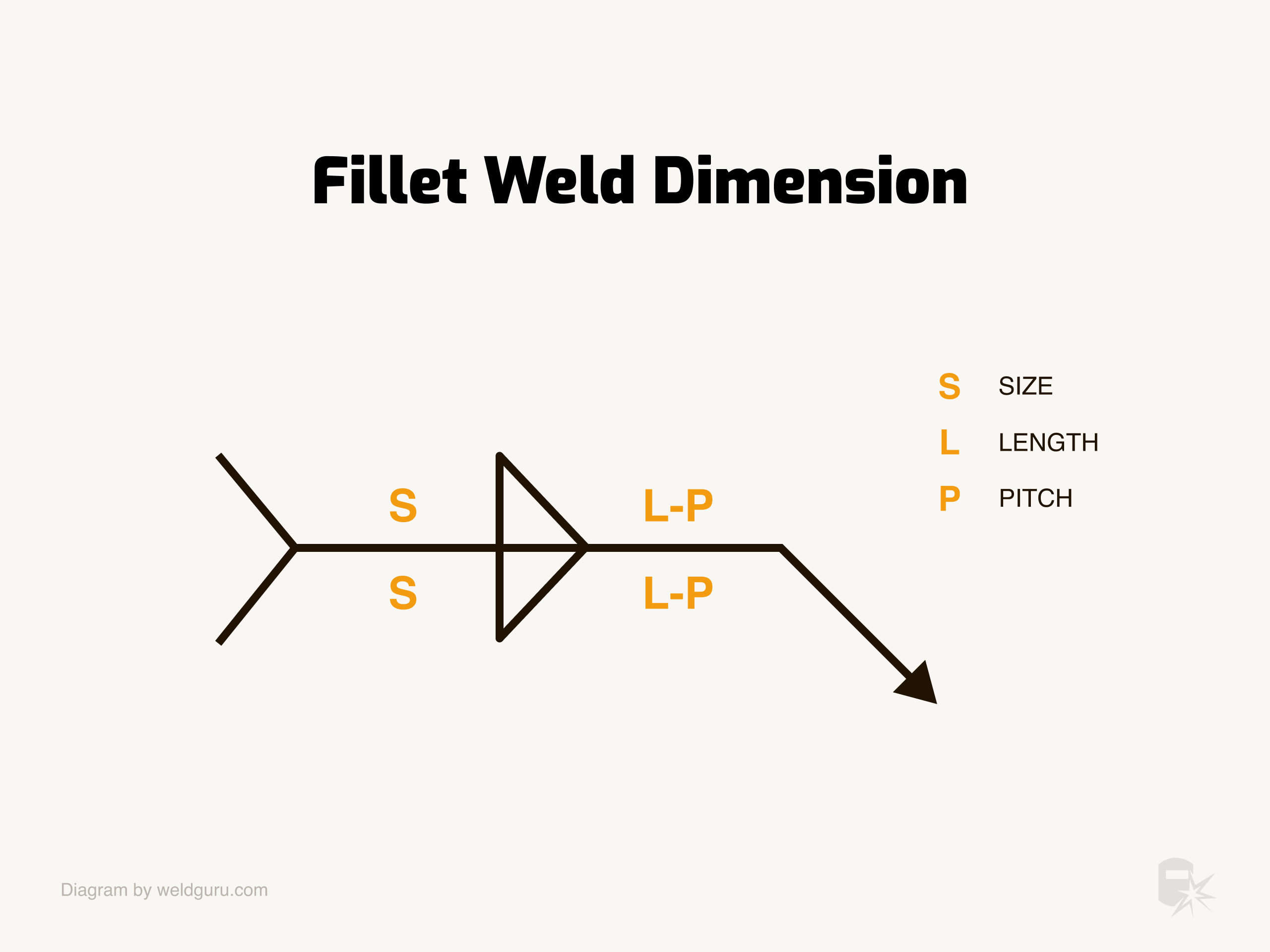

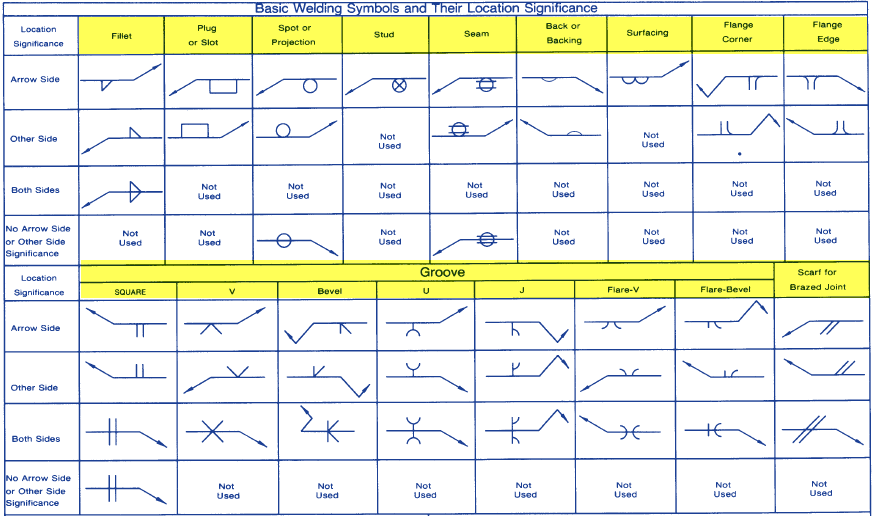

Fillet Weld Symbol Chart - Get free 30 page pdf welding symbols chart with applied examples for each symbol! The table presents some of the most commonly used welding symbols. This guide is designed to help you interpret welding symbols for fillet welds easily and quickly. Fillet welds account for the bulk of. It includes symbols for different types of welds like fillet, plug, spot, stud, seam, and back welds. For example, symbols for fillet, groove, plug, slot, seam, and surface welds are commonly used. Weld fillet or fillet weld is a basic type of weld for welding two or three members using a ‘t’ joint, lap joint, or corner joint configuration. These symbols, placed above, below, or on the reference line, convey additional. The document provides a chart of basic welding symbols and their locations and meanings. The only complete and official presentation of the standard welding symbols is in aws a2.4, standard symbols for welding, brazing, and nondestructive examinations. It includes symbols for different types of welds like fillet, plug, spot, stud, seam, and back welds. Learning welding symbols is not too complicated, but you don’t need to take a course to make. These additional symbols provide more detailed instructions about. For example, symbols for fillet, groove, plug, slot, seam, and surface welds are commonly used. Representing the type of weld (e.g., fillet weld, groove weld). You might see several supplementary weld symbols on a fillet welding symbol. This weld is used when the joint has two members coming together to form an intersection of commonly 90 degrees. Fillet welds account for the bulk of. These symbols give you extra information beyond length, pitch, and size, which is important to. Weld fillet or fillet weld is a basic type of weld for welding two or three members using a ‘t’ joint, lap joint, or corner joint configuration. The document provides a chart of basic welding symbols and their locations and meanings. Fillet welds account for the bulk of. You might see several supplementary weld symbols on a fillet welding symbol. These additional symbols provide more detailed instructions about. Learning welding symbols is not too complicated, but you don’t need to take a course to make. The only complete and official presentation of the standard welding symbols is in aws a2.4, standard symbols for welding, brazing, and nondestructive examinations. Representing the type of weld (e.g., fillet weld, groove weld). These symbols give you extra information beyond length, pitch, and size, which is important to. It includes symbols for different types of welds like fillet, plug, spot,. For example, symbols for fillet, groove, plug, slot, seam, and surface welds are commonly used. Fillet welds account for the bulk of. Weld fillet or fillet weld is a basic type of weld for welding two or three members using a ‘t’ joint, lap joint, or corner joint configuration. Fillet welds are one of the most common weld types in. For example, symbols for fillet, groove, plug, slot, seam, and surface welds are commonly used. You might see several supplementary weld symbols on a fillet welding symbol. Representing the type of weld (e.g., fillet weld, groove weld). This guide is designed to help you interpret welding symbols for fillet welds easily and quickly. The table presents some of the most. These additional symbols provide more detailed instructions about. Fillet welds are one of the most common weld types in the industry. These symbols give you extra information beyond length, pitch, and size, which is important to. The table presents some of the most commonly used welding symbols. The only complete and official presentation of the standard welding symbols is in. Get free 30 page pdf welding symbols chart with applied examples for each symbol! These symbols give you extra information beyond length, pitch, and size, which is important to. Name double sided v butt double sided bevel butt double sided u butt weld symbol name fillet resistance spot resistance steam name finish weld symbol on symbol base platform weld. For. These additional symbols provide more detailed instructions about. Fillet welds are one of the most common weld types in the industry. Representing the type of weld (e.g., fillet weld, groove weld). These symbols give you extra information beyond length, pitch, and size, which is important to. The document provides a chart of basic welding symbols and their locations and meanings. Learning welding symbols is not too complicated, but you don’t need to take a course to make. For example, symbols for fillet, groove, plug, slot, seam, and surface welds are commonly used. This guide is designed to help you interpret welding symbols for fillet welds easily and quickly. Weld fillet or fillet weld is a basic type of weld for. For example, symbols for fillet, groove, plug, slot, seam, and surface welds are commonly used. The document provides a chart of basic welding symbols and their locations and meanings. The only complete and official presentation of the standard welding symbols is in aws a2.4, standard symbols for welding, brazing, and nondestructive examinations. Fillet welds account for the bulk of. This. Fillet welds account for the bulk of. Weld fillet or fillet weld is a basic type of weld for welding two or three members using a ‘t’ joint, lap joint, or corner joint configuration. Get free 30 page pdf welding symbols chart with applied examples for each symbol! These symbols, placed above, below, or on the reference line, convey additional.. These additional symbols provide more detailed instructions about. The document provides a chart of basic welding symbols and their locations and meanings. The only complete and official presentation of the standard welding symbols is in aws a2.4, standard symbols for welding, brazing, and nondestructive examinations. Learning welding symbols is not too complicated, but you don’t need to take a course to make. The table presents some of the most commonly used welding symbols. These symbols give you extra information beyond length, pitch, and size, which is important to. This guide is designed to help you interpret welding symbols for fillet welds easily and quickly. For example, symbols for fillet, groove, plug, slot, seam, and surface welds are commonly used. Name double sided v butt double sided bevel butt double sided u butt weld symbol name fillet resistance spot resistance steam name finish weld symbol on symbol base platform weld. This weld is used when the joint has two members coming together to form an intersection of commonly 90 degrees. Get free 30 page pdf welding symbols chart with applied examples for each symbol! Fillet welds account for the bulk of. Fillet welds are one of the most common weld types in the industry. It includes symbols for different types of welds like fillet, plug, spot, stud, seam, and back welds.Welding Symbols Guide And Chart Fillet and Groove Weld

Welding Symbols How to Understand Them (With Charts) WaterWelders

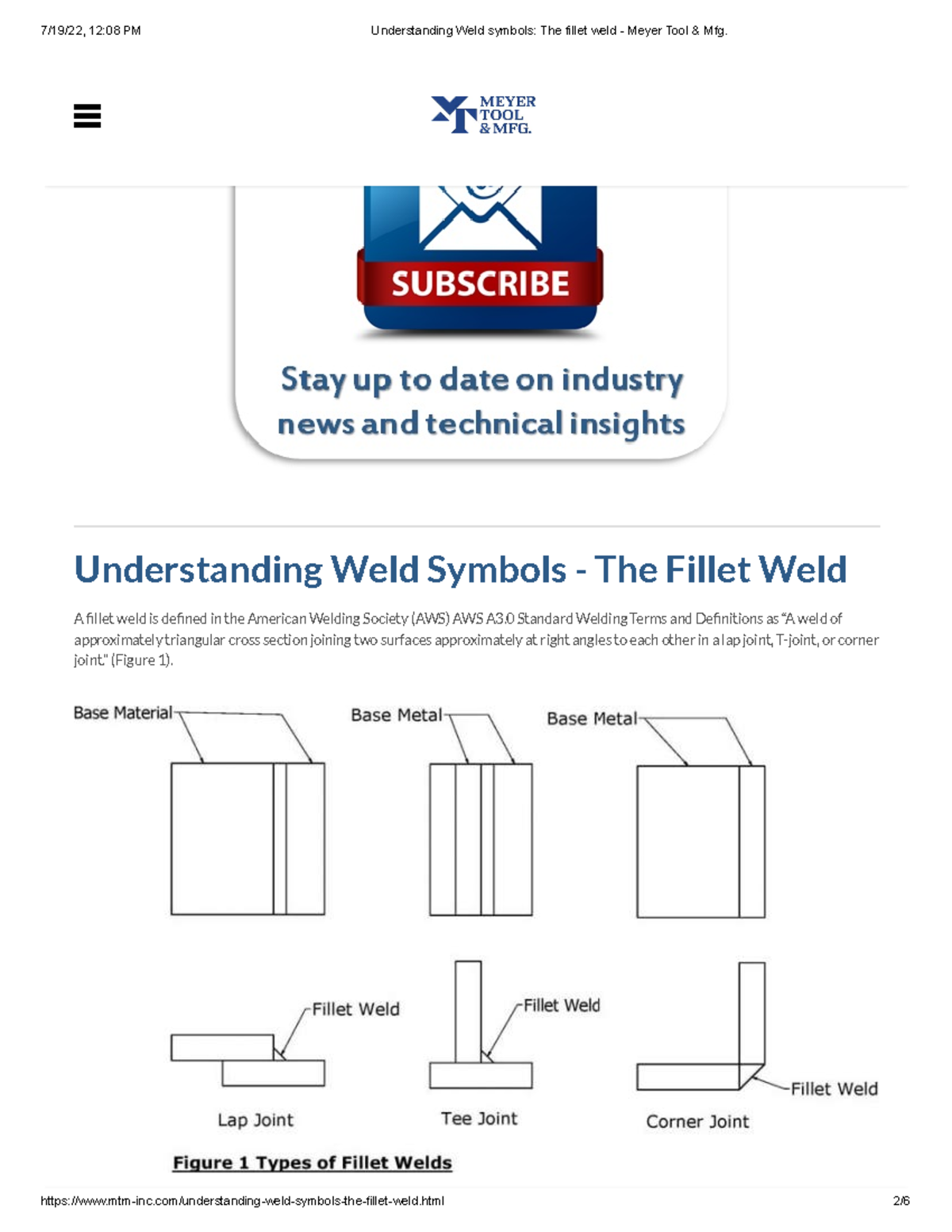

Fillet weld symbols Understanding Weld Symbols The Fillet Weld A llet weld is dened in the

Guide To Welding Symbols

Decoding Welding Symbols A Complete Guide to Fillet, Groove, and More

Printable Weld Symbol Chart

Fillet Weld Symbols Basic Guide Weld Guru

Welding Symbols Chart 8 X 10 Etsy UK

Welding Symbols

Welding Symbols Chart Printable

Representing The Type Of Weld (E.g., Fillet Weld, Groove Weld).

These Symbols, Placed Above, Below, Or On The Reference Line, Convey Additional.

You Might See Several Supplementary Weld Symbols On A Fillet Welding Symbol.

Weld Fillet Or Fillet Weld Is A Basic Type Of Weld For Welding Two Or Three Members Using A ‘T’ Joint, Lap Joint, Or Corner Joint Configuration.

Related Post: