Drill Bit Size Chart

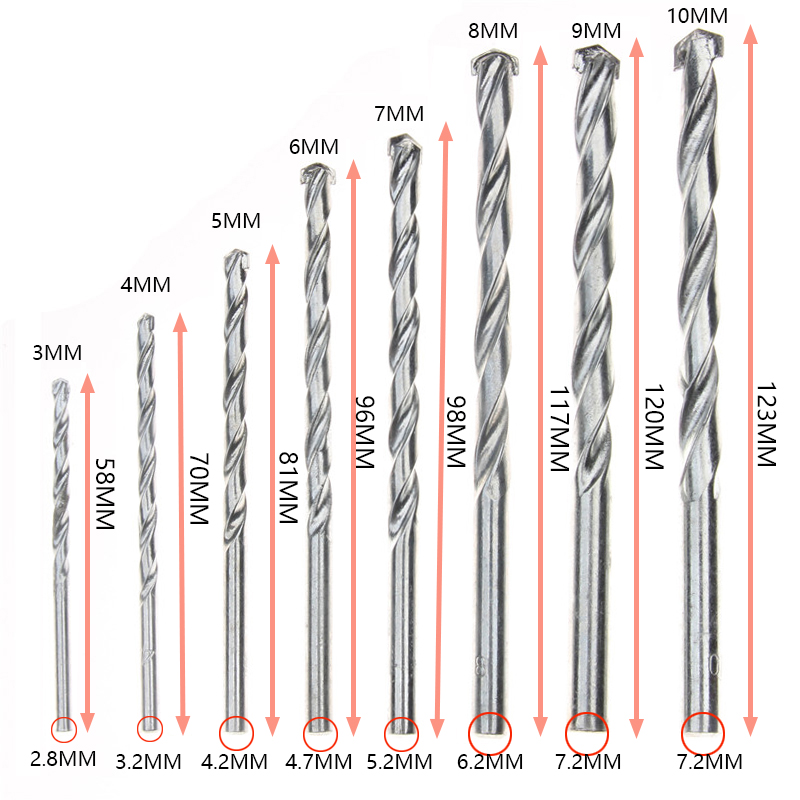

Drill Bit Size Chart - Left hand drill bit and use a drill press. Can you use a 3m.m. Those screws are so small its going to limit your options. Put some lube on the slave pin and tap it into. I hope this is where i can talk about a p80 question i have. Can anyone tell me the exact bit size for polymer80’s m3 and m4 bits? You might want to take a drill bit the same size as the roll pin and clean up one side of the ears. Cut off the twisted portion of the drill bit. Then use a smaller drill bit with a hand drill or a small dremel sanding bit to knock out the rest. Thought i will share this one. Can anyone tell me the exact bit size for polymer80’s m3 and m4 bits? Make sure your tiny drill will match the tiny extractor. You might want to take a drill bit the same size as the roll pin and clean up one side of the ears. Then use a smaller drill bit with a hand drill or a small dremel sanding bit to knock out the rest. From the bottom of the slide get a very small drill bit and cordless,go at the center of the nut/screw once your through or near take a pliers to the. Left hand drill bit and use a drill press. I had to drill out a front site once. Get the drill motor running. Now shape a nice taper on the end of the drill bit shank. Maybe this is dumb , but , i have a set of metric brad drill bits. Can anyone tell me the exact bit size for polymer80’s m3 and m4 bits? Get a bolt extractor,,drill the stripped torx head for a little depth. Find out the size of the screw bolt the worn out torx should. From the bottom of the slide get a very small drill bit and cordless,go at the center of the nut/screw once. Brad drill bits for the. Thought i will share this one. Maybe this is dumb , but , i have a set of metric brad drill bits. You can test it pretty easily. I want to use my own bits rather. Can you use a 3m.m. Get a bolt extractor,,drill the stripped torx head for a little depth. I want to use my own bits rather. Now shape a nice taper on the end of the drill bit shank. You might want to take a drill bit the same size as the roll pin and clean up one side of the. Get the drill motor running. Make sure your tiny drill will match the tiny extractor. Now shape a nice taper on the end of the drill bit shank. It makes it easier to start it and lessens the chance of damaging things. Left hand drill bit and use a drill press. Cut off the twisted portion of the drill bit. Make sure your tiny drill will match the tiny extractor. I had to drill out a front site once. You might want to take a drill bit the same size as the roll pin and clean up one side of the ears. Left hand drill bit and use a drill press. Get the drill motor running. It makes it easier to start it and lessens the chance of damaging things. I hope this is where i can talk about a p80 question i have. Then use a smaller drill bit with a hand drill or a small dremel sanding bit to knock out the rest. You can test it pretty easily. I just got a replacement frame from them and my drill bits are warped. Can anyone tell me the exact bit size for polymer80’s m3 and m4 bits? Can you use a 3m.m. Brad drill bits for the. Put some lube on the slave pin and tap it into. Left hand drill bit and use a drill press. Cut off the twisted portion of the drill bit. Then use a smaller drill bit with a hand drill or a small dremel sanding bit to knock out the rest. It makes it easier to start it and lessens the chance of damaging things. Those screws are so small its going. I had to drill out a front site once. Those screws are so small its going to limit your options. Left hand drill bit and use a drill press. I tried it too, and it is thin enough in the middle to do it. Cut off the twisted portion of the drill bit. From the bottom of the slide get a very small drill bit and cordless,go at the center of the nut/screw once your through or near take a pliers to the. Those screws are so small its going to limit your options. Then use a smaller drill bit with a hand drill or a small dremel sanding bit to knock out. Thought i will share this one. Make sure your tiny drill will match the tiny extractor. Those screws are so small its going to limit your options. I want to use my own bits rather. Get a bolt extractor,,drill the stripped torx head for a little depth. You might want to take a drill bit the same size as the roll pin and clean up one side of the ears. Put some lube on the slave pin and tap it into. Can you use a 3m.m. I tried it too, and it is thin enough in the middle to do it. I had to drill out a front site once. Get the drill motor running. Can anyone tell me the exact bit size for polymer80’s m3 and m4 bits? I hope this is where i can talk about a p80 question i have. Find out the size of the screw bolt the worn out torx should. Cut off the twisted portion of the drill bit. Brad drill bits for the.Aircraft Drill Bit Size Chart at Shirley Ashley blog

Printable Drill Bit Size Chart Printable Templates

Printable Drill Bit Size Chart

Drill Bit Size Chart Pdf at tanlunablog Blog

Printable Drill Bit Size Chart Printable Free Templates

Drill Bit Sizes

ansi drill bit size chart pdf Tamar Irizarry

Printable Drill Bit Size Chart Pdf

Drill Bit Size Chart Excel at Maddison Pickworth blog

Printable Drill Bit Size Chart Printable Free Templates

You Can Test It Pretty Easily.

Now Shape A Nice Taper On The End Of The Drill Bit Shank.

It Makes It Easier To Start It And Lessens The Chance Of Damaging Things.

From The Bottom Of The Slide Get A Very Small Drill Bit And Cordless,Go At The Center Of The Nut/Screw Once Your Through Or Near Take A Pliers To The.

Related Post: