Countersink Chart

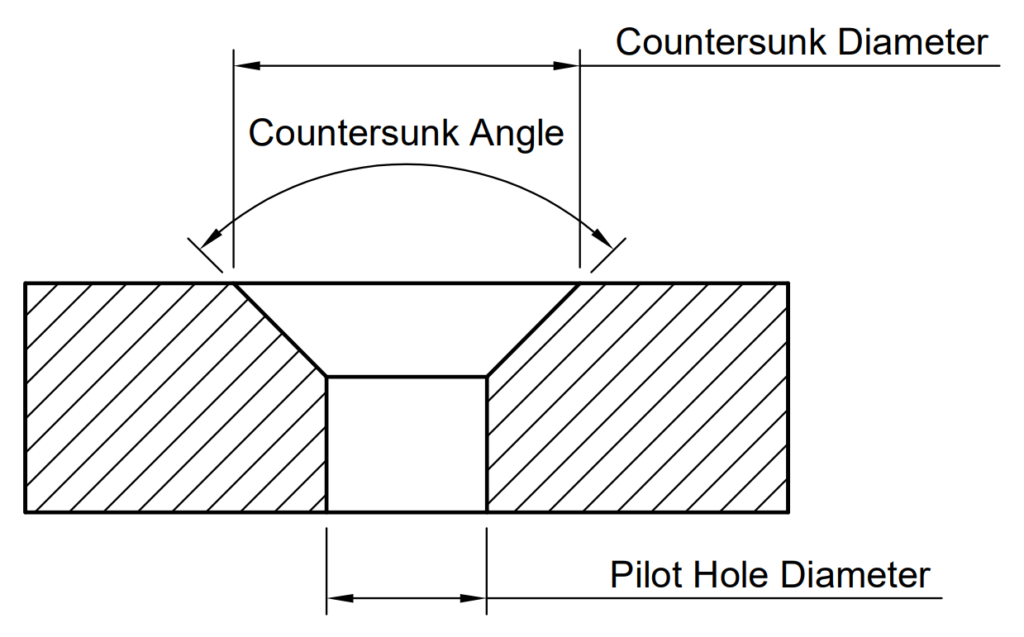

Countersink Chart - Quickly change between drilling countersunk holes and driving screws. This keeps the part’s outer layer smooth, which can. Countersinking is the process of cutting a conical hole into a material to allow a fastener like a screw to be driven into the material deep enough for its head to be flush with (or. Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for holes/bits. A countersink hole is a conical hole or depression in a material, typically around the edge of a hole. The “conical” feature is what differentiates a countersunk hole from a. Countersinking holes are conical holes designed to seat the head of a screw, bolt, or fastener so it sits flush with or just below the surface. If you want to make your next woodworking project look clean. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for holes/bits. In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for. In manufacturing, a countersink (symbol: Countersinking a screw helps the screw head lie flush with the surface of the wood to better conceal the hardware. ⌵) is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. This keeps the part’s outer layer smooth, which can. Quickly change between drilling countersunk holes and driving screws. The “conical” feature is what differentiates a countersunk hole from a. If you want to make your next woodworking project look clean. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for holes/bits. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Countersinking is the process of. Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for holes/bits. This keeps the part’s outer layer smooth, which can. Countersinking is the process of cutting a conical hole into a material to allow a fastener like a screw to be driven into the material deep enough for its. Countersinking a screw helps the screw head lie flush with the surface of the wood to better conceal the hardware. This keeps the part’s outer layer smooth, which can. The “conical” feature is what differentiates a countersunk hole from a. ⌵) is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for holes/bits. A countersink consists of a. ⌵) is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Understand the types and use of countersink drill. The purpose of a countersink. A countersink hole is a conical hole or depression in a material, typically around the edge of a hole. The “conical” feature is what differentiates a countersunk hole from a. If you want to make your next woodworking project look clean. Understand the types and use of countersink drill bit, countersink vs counterbore hole and. If you want to make your next woodworking project look clean. Countersinking holes are conical holes designed to seat the head of a screw, bolt, or fastener so it sits flush with or just below the surface. In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. The “conical” feature is what differentiates a countersunk hole from a. If you want to make your next woodworking project look clean. Understand the types and use. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. This keeps the part’s outer layer smooth, which can. In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call. The “conical” feature is what differentiates a countersunk hole from a. Quickly change between drilling countersunk holes and driving screws. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Countersinking is the process of cutting a conical hole into a material. If you want to make your next woodworking project look clean. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. The “conical” feature is what differentiates a countersunk hole from a. Countersinking is the process of cutting a conical hole into a material to allow a fastener like a screw to be driven into the material deep enough for its head to be flush with (or. In manufacturing, a countersink (symbol: Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for holes/bits. A countersink hole is a conical hole or depression in a material, typically around the edge of a hole. The purpose of a countersink. In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for. ⌵) is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. Quickly change between drilling countersunk holes and driving screws. This keeps the part’s outer layer smooth, which can.100 Degree Countersink Chart A Visual Reference of Charts Chart Master

Countersink Size Chart at Angela Bates blog

Metric Countersunk Hole Dimensions Chart A Pictures Of Hole 2018

Counterbore Hole Dimensions Chart Metric at James Goldsbrough blog

Countersink Holes Chart for Drilling Wood Screws Drill Bit Size Guide

Standard Counter Depths at Christy Calvin blog

Metric Countersunk Hole Dimensions Chart A Pictures Of Hole 2018

Metric Countersunk Hole Dimensions Chart A Pictures Of Hole 2018

Countersunk Hole Size for 100 Degree Machine Screw (ANSI Inch)

Countersink 90° d1=13,4mm d2=8mm DamenCNC B.V.

Countersinking Holes Are Conical Holes Designed To Seat The Head Of A Screw, Bolt, Or Fastener So It Sits Flush With Or Just Below The Surface.

Countersinking A Screw Helps The Screw Head Lie Flush With The Surface Of The Wood To Better Conceal The Hardware.

A Countersink Is An Angled Taper Applied To A Hole That Allows A Fastener (Usually A Flat Head Screw Or Similar) To Sit Even With, Or Below The Surface Which Has Been Countersunk.

Related Post: