Calibration Lens Chart

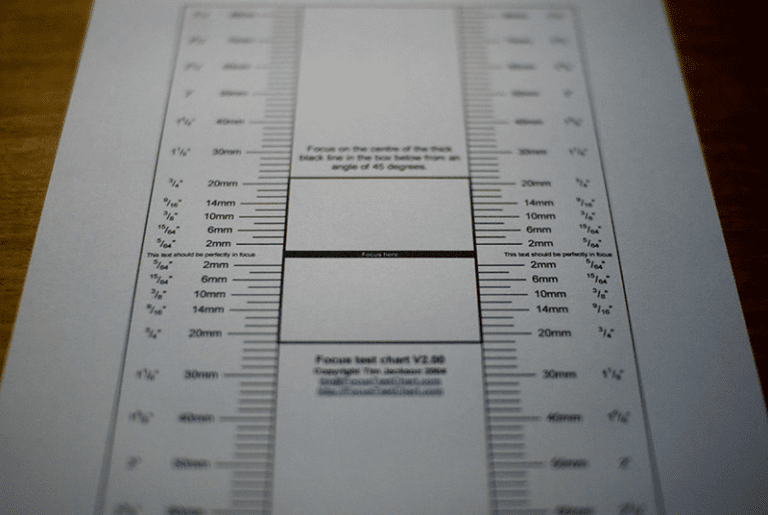

Calibration Lens Chart - Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. Calibration keeps results honest and trustworthy, which counts Discover the critical role of calibration in industrial manufacturing. Calibration is the act of comparing a device under test (dut) of an unknown value with a reference standard of a known value. Learn how it mitigates risks, reduces costs, and ensures compliance. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. It ensures that the instrument. At its core, calibration is the process of comparing the performance of a measurement device (such as a thermometer, scale, or pressure gauge) against a recognized. A person typically performs a calibration to determine. A person typically performs a calibration to determine. Discover the critical role of calibration in industrial manufacturing. Calibration is the process of comparing the readings of a measuring instrument with a known standard value and making adjustments if needed. The process of comparison of a device with unknown accuracy to a device with a known, accurate standard to eliminate any variation in the device being checked is called calibration. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. It ensures that the instrument. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. Calibration keeps results honest and trustworthy, which counts To calibrate testing equipment is to level gear so measurements remain accurate and consistent. Calibration is the act of comparing a device under test (dut) of an unknown value with a reference standard of a known value. Discover the critical role of calibration in industrial manufacturing. It ensures that the instrument. To calibrate testing equipment is to level gear so measurements remain accurate and consistent. The process of comparison of a device with unknown accuracy to a device with a known, accurate standard to eliminate any variation in the device being checked is called calibration. In measurement. Calibration is the process of comparing the readings of a measuring instrument with a known standard value and making adjustments if needed. A person typically performs a calibration to determine. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. The. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. It ensures that the. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. To calibrate testing equipment is to level gear so measurements remain accurate and consistent. At its core, calibration is the process of comparing the performance of a measurement device (such as. Learn how it mitigates risks, reduces costs, and ensures compliance. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. Discover the critical role of calibration in industrial manufacturing. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a. Learn how it mitigates risks, reduces costs, and ensures compliance. Calibration is the process of comparing the readings of a measuring instrument with a known standard value and making adjustments if needed. It ensures that the instrument. A person typically performs a calibration to determine. At its core, calibration is the process of comparing the performance of a measurement device. At its core, calibration is the process of comparing the performance of a measurement device (such as a thermometer, scale, or pressure gauge) against a recognized. The process of comparison of a device with unknown accuracy to a device with a known, accurate standard to eliminate any variation in the device being checked is called calibration. Learn how it mitigates. Calibration is the process of comparing the readings of a measuring instrument with a known standard value and making adjustments if needed. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. A person typically performs a calibration to determine. The process of comparison of a device with unknown accuracy to. Calibration is the act of comparing a device under test (dut) of an unknown value with a reference standard of a known value. Calibration keeps results honest and trustworthy, which counts A person typically performs a calibration to determine. Discover the critical role of calibration in industrial manufacturing. Calibration is the process of adjusting and verifying the accuracy of a. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. Calibration is the process of comparing the readings of a measuring instrument with a known standard value and making adjustments if needed. A person typically performs a calibration to determine. In measurement technology and metrology, calibration is the comparison of measurement. A person typically performs a calibration to determine. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. At its core, calibration is the process of comparing the performance of a measurement device (such as a thermometer, scale, or pressure gauge) against a recognized. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Discover the critical role of calibration in industrial manufacturing. The process of comparison of a device with unknown accuracy to a device with a known, accurate standard to eliminate any variation in the device being checked is called calibration. Learn how it mitigates risks, reduces costs, and ensures compliance. It ensures that the instrument. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. To calibrate testing equipment is to level gear so measurements remain accurate and consistent.DIY lens focus adjustment calibration chart / tool. http//www.squit.co.uk/photo/files

Printable Lens Focus Chart Printable Word Searches

Free Lens Calibration Chart

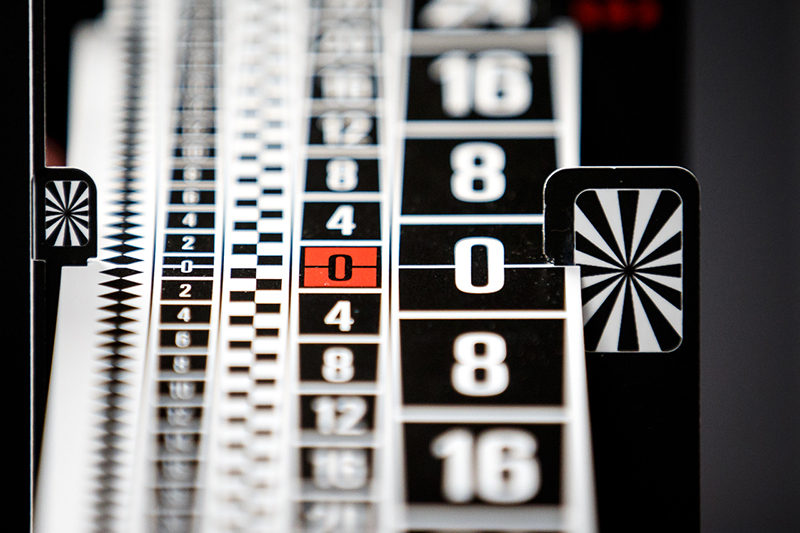

Focus Calibration Chart at Ronald Piper blog

Calibration Chart Microscope

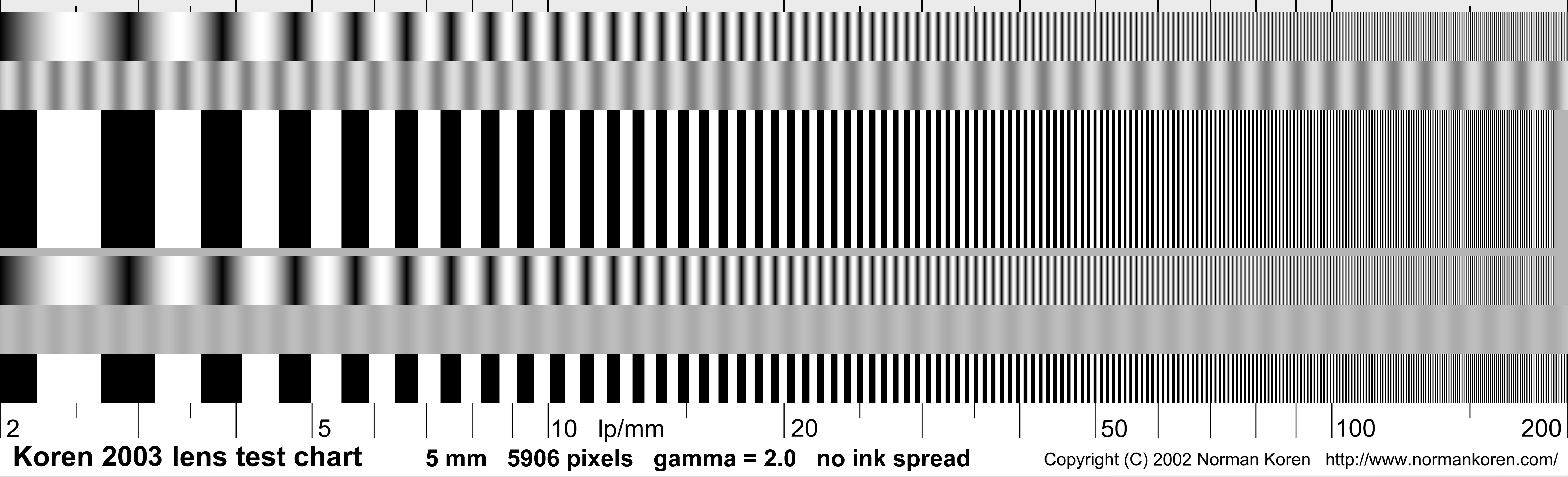

Lens testing

Photos looking soft? You need a FREE Lens Calibration Chart! Christopher Leach Photography

Lens Calibration Chart Pdf

Tips On How to Calibrate Camera Lens 2024

Dslr Lens Calibration Chart at Harrison Humphery blog

Calibration Is The Act Of Comparing A Device Under Test (Dut) Of An Unknown Value With A Reference Standard Of A Known Value.

Calibration Keeps Results Honest And Trustworthy, Which Counts

Calibration Is The Process Of Comparing The Readings Of A Measuring Instrument With A Known Standard Value And Making Adjustments If Needed.

Related Post: