C Chart

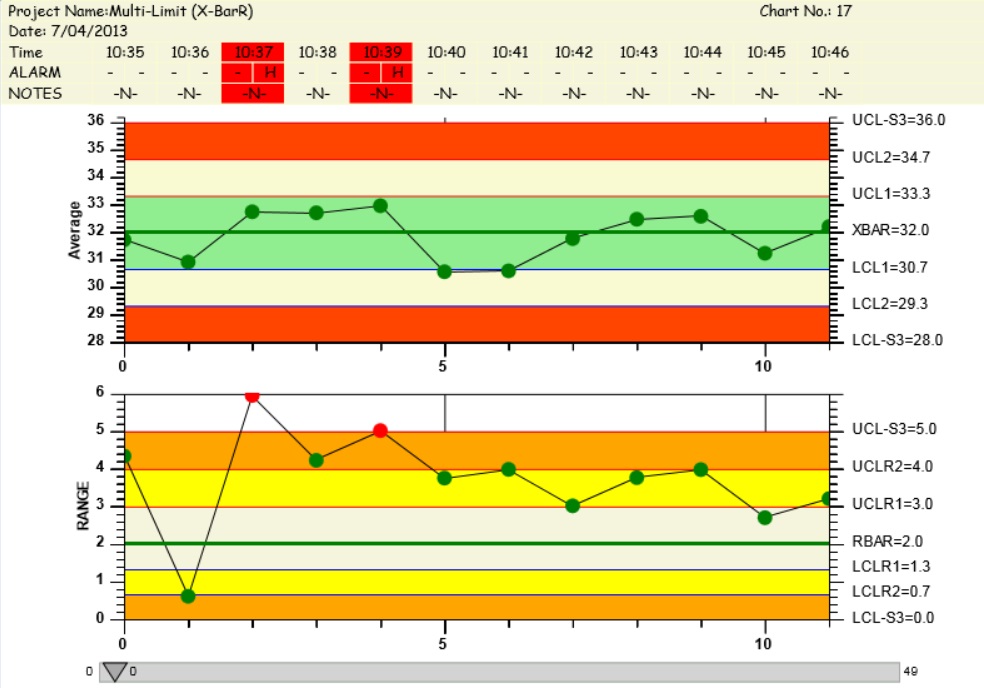

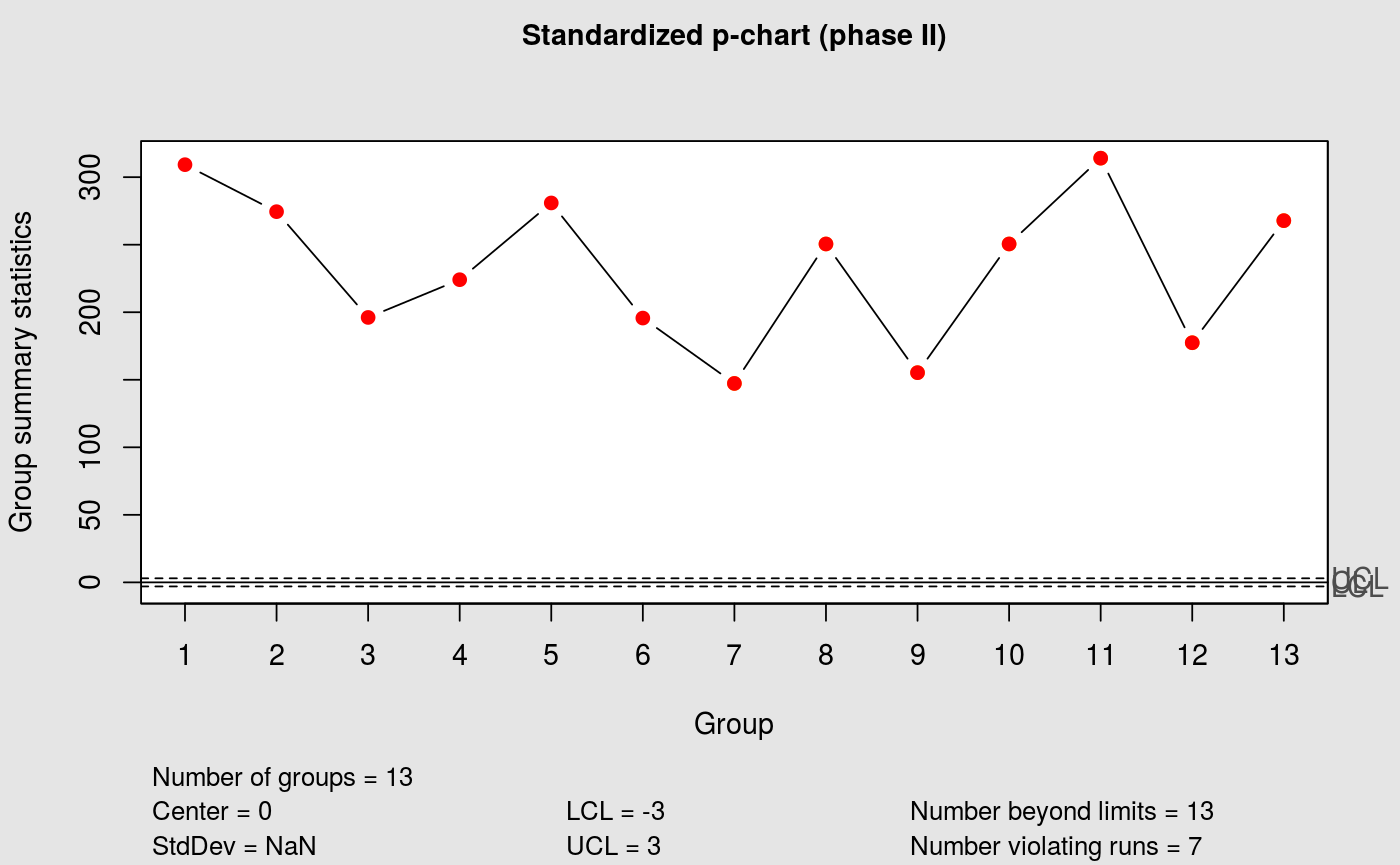

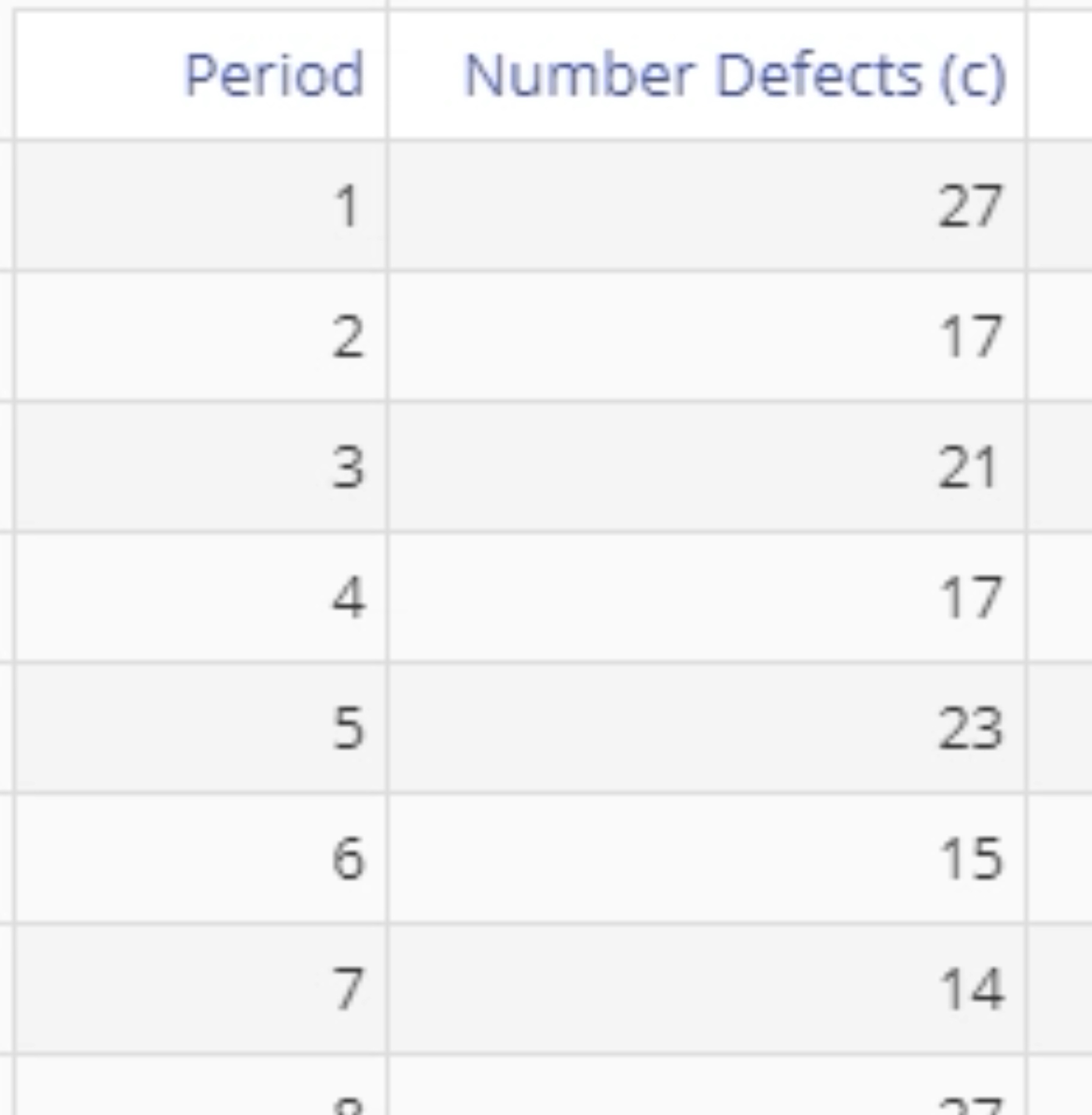

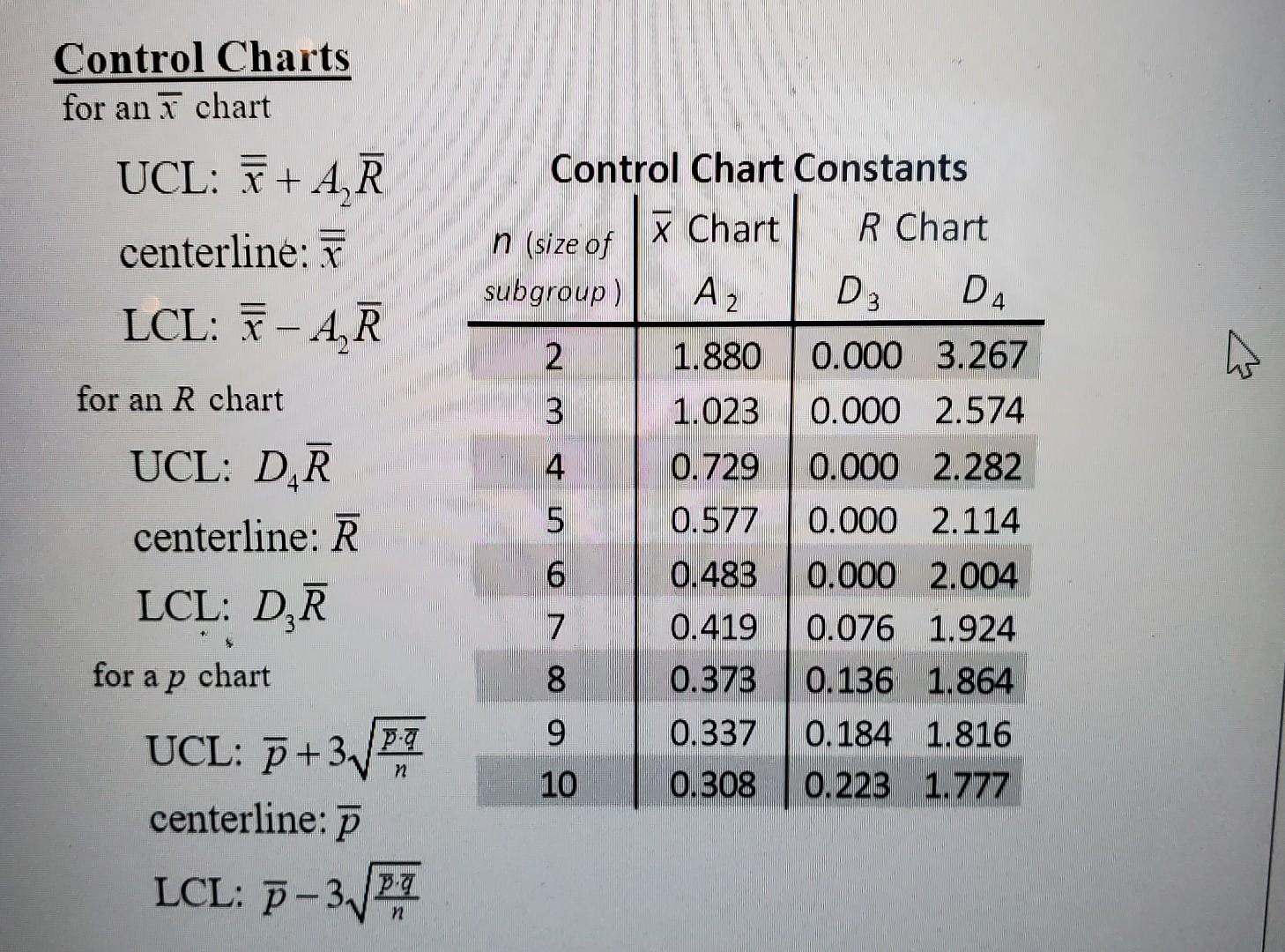

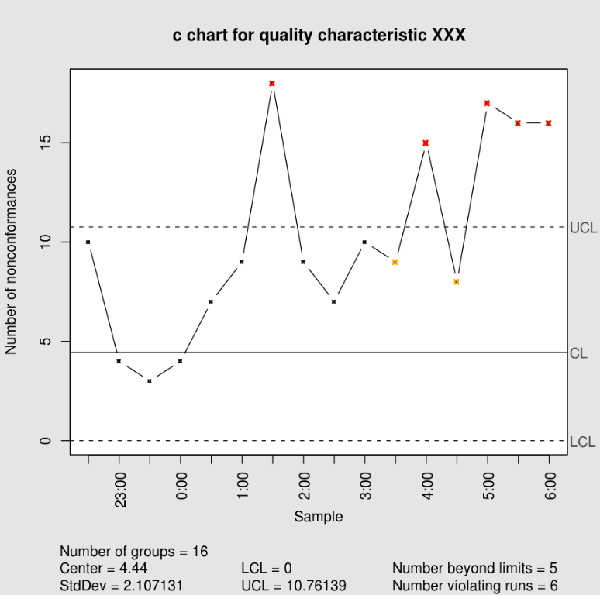

C Chart - Sample averages, a centerline, and control limits. The c chart formulas are (doty,. The c chart is sensitive to changes in the number of defective items in the. It is also occasionally used to monitor. Its reliance on the poisson distribution for calculating control limits. A c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken from a process (misra, 2008). A c chart is a control chart for monitoring the number of defects per sample. A c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. C chart is also known as the control chart for defects (counting of the number of defects). The c chart is a powerful lean six sigma tool for managing process quality through the monitoring of defect counts. It is also occasionally used to monitor. C chart is also known as the control chart for defects (counting of the number of defects). The c chart is sensitive to changes in the number of defective items in the. It means that there are only common causes of variation present (see january 2004 publication on variation, available on the web. For a sample subgroup (also called the inspection unit), the number of times a defect occurs is. Control charts generally have three parts: Sample averages, a centerline, and control limits. A c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. What does it mean when the c chart is in statistical control? Its reliance on the poisson distribution for calculating control limits. What does it mean when the c chart is in statistical control? A c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken from a process (misra, 2008). It means that there are only common causes of variation present (see january 2004 publication on variation, available on the. A c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken from a process (misra, 2008). This “unit” is commonly referred to as an inspection unit and may be “per day” or “per. It is used to track the number of defects within units with constant sizes. What. The c chart is sensitive to changes in the number of defective items in the. A c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken from a process (misra, 2008). Its reliance on the poisson distribution for calculating control limits. What does it mean when the c. A c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. The c chart is a powerful lean six sigma tool for managing process quality through the monitoring of defect counts. C chart is also known as the control chart for defects (counting of the number of defects). It is generally. It is generally used to monitor the number of defects in constant size. Its reliance on the poisson distribution for calculating control limits. It is used to track the number of defects within units with constant sizes. The c chart is sensitive to changes in the number of defective items in the. The c chart measures the number of nonconformities. It is used to track the number of defects within units with constant sizes. A c chart is a control chart for monitoring the number of defects per sample. A c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. The c chart is a powerful lean six sigma tool for. What does it mean when the c chart is in statistical control? A c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. This “unit” is commonly referred to as an inspection unit and may be “per day” or “per. It is generally used to monitor the number of defects in. Its reliance on the poisson distribution for calculating control limits. A c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. It is also occasionally used to monitor. What does it mean when the c chart is in statistical control? It is used to track the number of defects within units. For a sample subgroup (also called the inspection unit), the number of times a defect occurs is. Sample averages, a centerline, and control limits. This “unit” is commonly referred to as an inspection unit and may be “per day” or “per. It is used to track the number of defects within units with constant sizes. What does it mean when. This “unit” is commonly referred to as an inspection unit and may be “per day” or “per. It is also occasionally used to monitor. For a sample subgroup (also called the inspection unit), the number of times a defect occurs is. It means that there are only common causes of variation present (see january 2004 publication on variation, available on. It is used to track the number of defects within units with constant sizes. Control charts generally have three parts: It means that there are only common causes of variation present (see january 2004 publication on variation, available on the web. Its reliance on the poisson distribution for calculating control limits. The c chart is a powerful lean six sigma tool for managing process quality through the monitoring of defect counts. A c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. It is generally used to monitor the number of defects in constant size. The c chart measures the number of nonconformities per “unit” and is denoted by c. What is a c chart? This “unit” is commonly referred to as an inspection unit and may be “per day” or “per. The c chart is sensitive to changes in the number of defective items in the. The c chart formulas are (doty,. It is also occasionally used to monitor. Sample averages, a centerline, and control limits. C chart is also known as the control chart for defects (counting of the number of defects).22 C CHART IN SIX SIGMA, IN C CHART SIX SIGMA Chart & Formation

What Is P Chart And C Chart at Robert Myers blog

c Chart Tutorial MoreSteam

c chart control x axis scale C chart

SPC 4 c chart (Control Chart for number defective) YouTube

c Chart Tutorial MoreSteam

Statistical Process Control PresentationEZE

SOLVED tt+++ Use following information to answer Q8 and9. Orlando Crafts has decided to use a

C Chart Definition, Formulas Statistics How To

Control chart, C chart, U chart difference of C chart & U chart, attribute control chart YouTube

A C Chart Is A Control Chart For Monitoring The Number Of Defects Per Sample.

For A Sample Subgroup (Also Called The Inspection Unit), The Number Of Times A Defect Occurs Is.

A C Chart Is A Type Of Control Chart That Shows How Many Defects Or Nonconformities Are In Samples Of Constant Size, Taken From A Process (Misra, 2008).

What Does It Mean When The C Chart Is In Statistical Control?

Related Post: