Anodization Chart

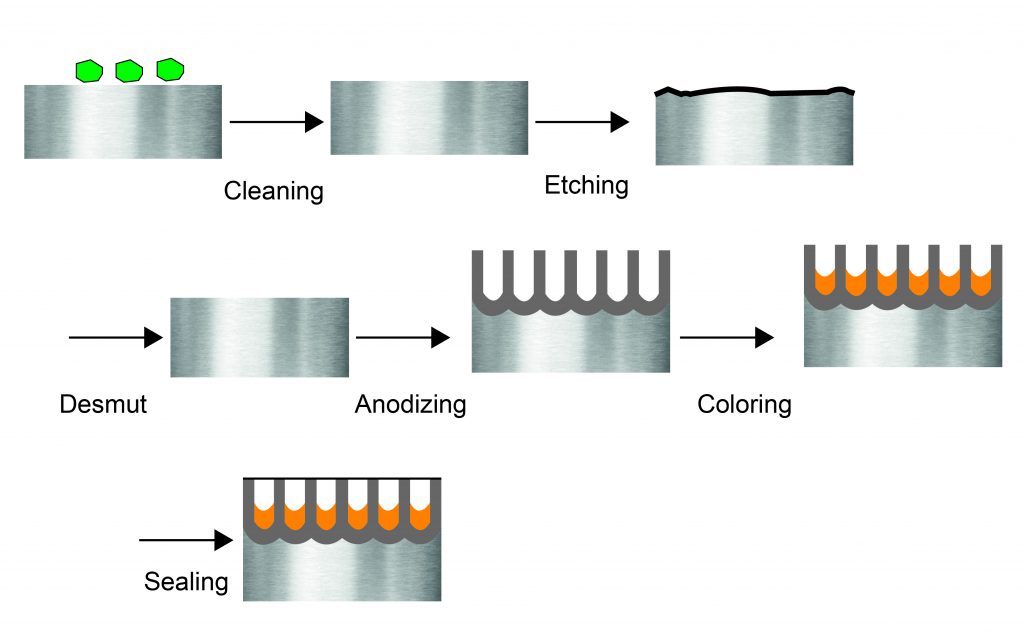

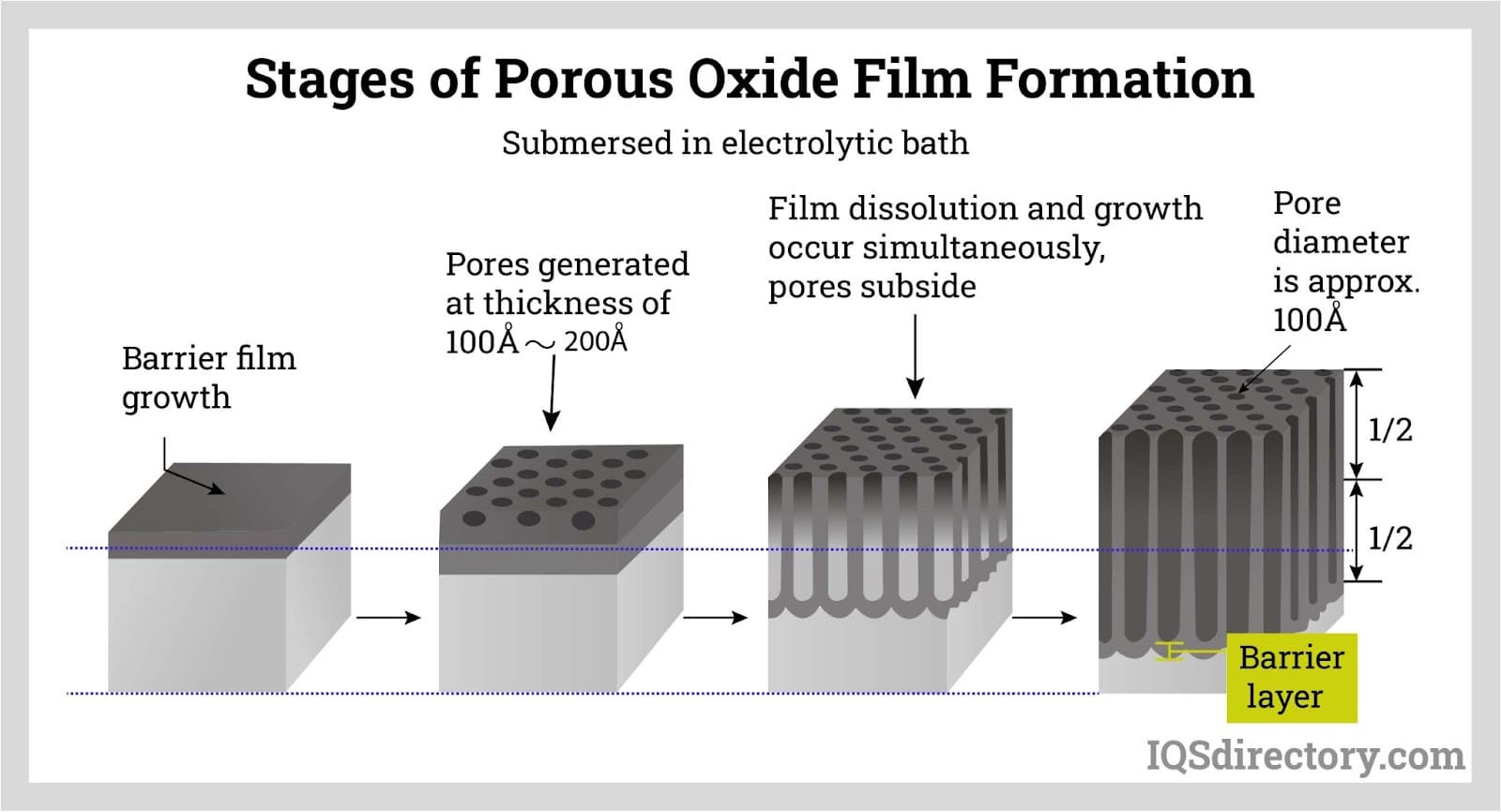

Anodization Chart - The process is called anodizing because the part to be. Anodization converts traditional metal surfaces to a beautiful, durable, and high performing interior solution by implementing an accelerated. Anodization is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. What is anodizing and why is it important? A limited number of metals, such as stainless steels,. The resulting finish, depending on the process, is the second hardest substance known. Anodizing is a key step in manufacturing aluminum cnc machined parts. It is an electrolytic process. Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Aluminum is ideally suited to anodizing,. An electrochemical process that involves coating a metal part with an oxide surface layer, anodizing gives the part. Anodizing is an electrochemical technique that improves both the functionality and appearance of nonferrous metals, most commonly aluminum and its alloys, but also copper,. What is anodizing and why is it important? Anodizing consists of electrically depositing an oxide film from aqueous solution onto the surface of a metal, often aluminum, which serves as the anode in an electrolytic cell. Aluminum is ideally suited to anodizing,. Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. The process is called anodizing because the part to be. A limited number of metals, such as stainless steels,. Anodization converts traditional metal surfaces to a beautiful, durable, and high performing interior solution by implementing an accelerated. The resulting finish, depending on the process, is the second hardest substance known. What is anodizing and why is it important? Aluminum is ideally suited to anodizing,. It is an electrolytic process. An electrochemical process that involves coating a metal part with an oxide surface layer, anodizing gives the part. It is an electrochemical process that thickens and toughens the naturally occurring protective oxide. The resulting finish, depending on the process, is the second hardest substance known. What is anodizing and why is it important? A limited number of metals, such as stainless steels,. Anodizing consists of electrically depositing an oxide film from aqueous solution onto the surface of a metal, often aluminum, which serves as the anode in an electrolytic cell. The process. Aluminum is ideally suited to anodizing,. Anodization converts traditional metal surfaces to a beautiful, durable, and high performing interior solution by implementing an accelerated. The process is called anodizing because the part to be. It is an electrochemical process that thickens and toughens the naturally occurring protective oxide. Anodizing is a key step in manufacturing aluminum cnc machined parts. Anodizing is an electrochemical technique that improves both the functionality and appearance of nonferrous metals, most commonly aluminum and its alloys, but also copper,. Anodizing is a key step in manufacturing aluminum cnc machined parts. Anodizing consists of electrically depositing an oxide film from aqueous solution onto the surface of a metal, often aluminum, which serves as the anode in. It is an electrolytic process. Aluminum is ideally suited to anodizing,. Anodizing consists of electrically depositing an oxide film from aqueous solution onto the surface of a metal, often aluminum, which serves as the anode in an electrolytic cell. The process is called anodizing because the part to be. Anodization is an electrolytic passivation process used to increase the thickness. Anodizing consists of electrically depositing an oxide film from aqueous solution onto the surface of a metal, often aluminum, which serves as the anode in an electrolytic cell. It is an electrolytic process. Aluminum is ideally suited to anodizing,. The process is called anodizing because the part to be. The resulting finish, depending on the process, is the second hardest. Anodization is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. An electrochemical process that involves coating a metal part with an oxide surface layer, anodizing gives the part. Anodizing is an electrochemical technique that improves both the functionality and appearance of nonferrous metals, most commonly aluminum and its. It is an electrochemical process that thickens and toughens the naturally occurring protective oxide. What is anodizing and why is it important? The process is called anodizing because the part to be. Anodizing is a key step in manufacturing aluminum cnc machined parts. It is an electrolytic process. Anodization is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodization converts traditional metal surfaces to a beautiful, durable, and high performing interior solution by implementing an accelerated. Anodizing consists of electrically depositing an oxide film from aqueous solution onto the surface of a metal, often aluminum, which. Anodization converts traditional metal surfaces to a beautiful, durable, and high performing interior solution by implementing an accelerated. Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodizing is a key step in manufacturing aluminum cnc machined parts. An electrochemical process that involves coating a metal part. Anodization is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodizing is a key step in manufacturing aluminum cnc machined parts. It is an electrochemical process that thickens and toughens the naturally occurring protective oxide. Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodizing is an electrochemical technique that improves both the functionality and appearance of nonferrous metals, most commonly aluminum and its alloys, but also copper,. Anodization converts traditional metal surfaces to a beautiful, durable, and high performing interior solution by implementing an accelerated. A limited number of metals, such as stainless steels,. An electrochemical process that involves coating a metal part with an oxide surface layer, anodizing gives the part. The resulting finish, depending on the process, is the second hardest substance known. It is an electrolytic process. What is anodizing and why is it important?Your Basic Guide on How to Anodize Aluminum Parts rapiddirect

Us Anodizing Color Chart Paint Color Options Are Changing At

Anodization Chart

Aluminum Anodizing Color Chart

How to Anodize Aluminum Type II Anodizing for Beginners AluConsult

aluminum anodized color chart Anodized aluminum sheet colors for selection

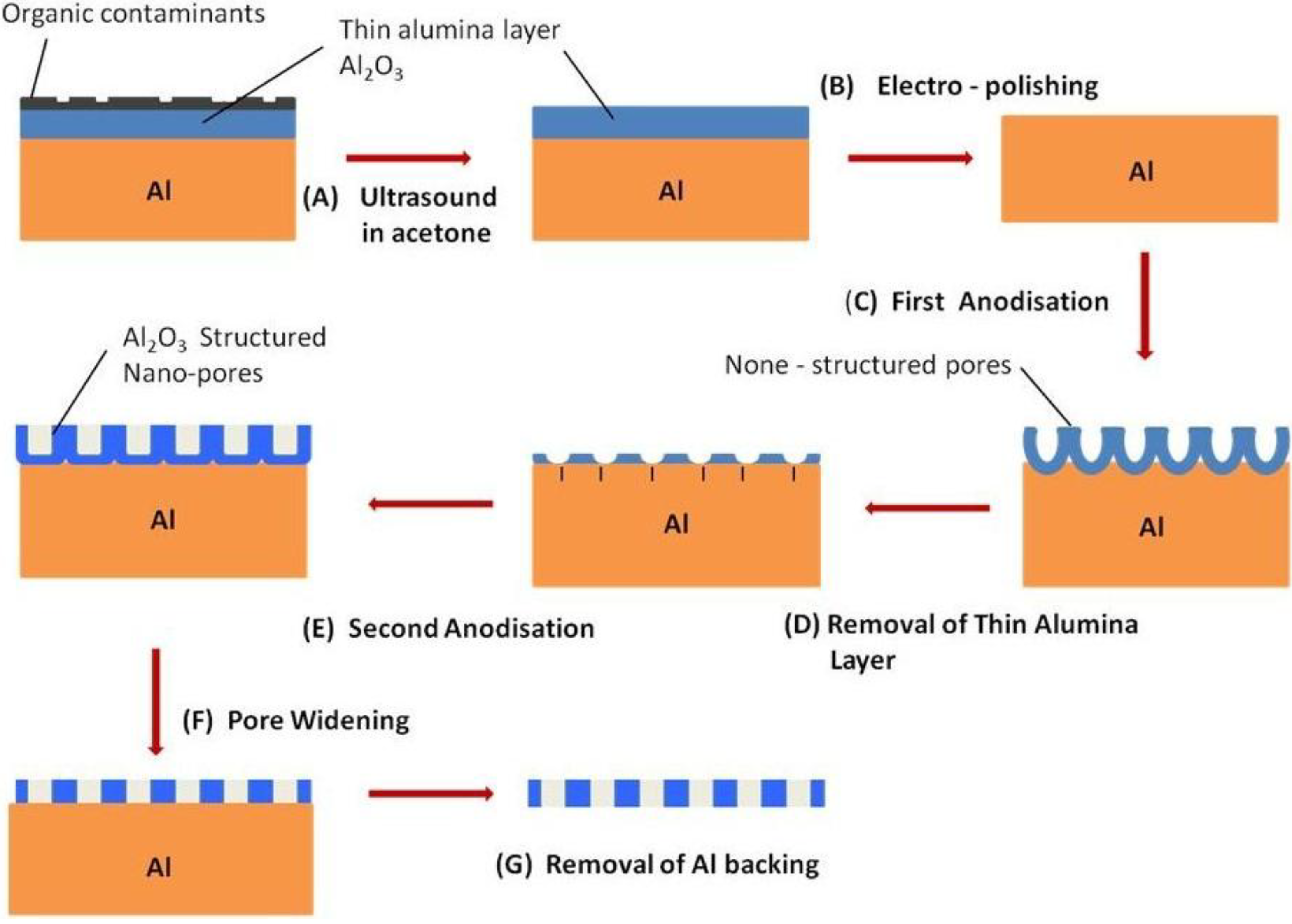

Materials Free FullText Progress in NanoEngineered Anodic Aluminum Oxide Membrane Development

What Is Anodizing Process Types And Advantages Non Fe vrogue.co

Aluminum Anodizing Chart at Indiana Brownless blog

Aluminum Anodizing Types at Barry Burgess blog

Anodizing Consists Of Electrically Depositing An Oxide Film From Aqueous Solution Onto The Surface Of A Metal, Often Aluminum, Which Serves As The Anode In An Electrolytic Cell.

The Process Is Called Anodizing Because The Part To Be.

Aluminum Is Ideally Suited To Anodizing,.

Related Post:

- WATERMARK.png/:/rs=w:1240,cg:true,m)