6010 Welding Rod Amperage Chart

6010 Welding Rod Amperage Chart - I know the test for 2 xx heavy wall is different from 6 but for me. Sorry if this has been posted before, but im having a problem with my 6010 electrode freezing everytime i try to do roots on butt welds, no matter if its vertical, horizontal,. Being a structural hand, and not running a lot of 6010. I am trying to learn horizontal fillet welds using 1/8 6010 electrodes. That said, arc force would have been nice.but for the tig machine it is, your experience sounds more. The operating characteristics, mechanical properties, and welding applications of the 6011 resemble those of the 6010, but the 6011 requires alternating current. I'm sure your are aware to keep the rod basically pointed towards. One of the main problems that i am having is getting the first pass in straight. Lincoln 6010 5p+ is my new favorite rod. Also should be used 1/8 electrode. I run at 90 amps, and am very pleased with my welds. I know the test for 2 xx heavy wall is different from 6 but for me. Being a structural hand, and not running a lot of 6010. I am trying to learn horizontal fillet welds using 1/8 6010 electrodes. One of the main problems that i am having is getting the first pass in straight. Once i start the arc i can't. If i go up to 95, or even 100. I'm surprised it will keep the 6010 lit, something i haven't even expected. That said, arc force would have been nice.but for the tig machine it is, your experience sounds more. I use these with my lincoln invertec 275 and sa200. Also should be used 1/8 electrode. Sorry if this has been posted before, but im having a problem with my 6010 electrode freezing everytime i try to do roots on butt welds, no matter if its vertical, horizontal,. They don't work well on small portable engine driven welders. I get the same results,. Once i start the arc i can't. We ran into some problems. Ive been practicing vertical up fillets with 3/32 7018. I run at 90 amps, and am very pleased with my welds. That said, arc force would have been nice.but for the tig machine it is, your experience sounds more. I get the same results,. Sorry if this has been posted before, but im having a problem with my 6010 electrode freezing everytime i try to do roots on butt welds, no matter if its vertical, horizontal,. Being a structural hand, and not running a lot of 6010. They don't work well on small portable engine driven welders. I know the test for 2 xx. Once i start the arc i can't. I'm surprised it will keep the 6010 lit, something i haven't even expected. That said, arc force would have been nice.but for the tig machine it is, your experience sounds more. I get the same results,. They don't work well on small portable engine driven welders. We ran into some problems. I use these with my lincoln invertec 275 and sa200. I'm surprised it will keep the 6010 lit, something i haven't even expected. I get the same results,. I am trying to learn horizontal fillet welds using 1/8 6010 electrodes. I run at 90 amps, and am very pleased with my welds. I know the test for 2 xx heavy wall is different from 6 but for me. I use these with my lincoln invertec 275 and sa200. One of the main problems that i am having is getting the first pass in straight. I get the same results,. One of the main problems that i am having is getting the first pass in straight. That said, arc force would have been nice.but for the tig machine it is, your experience sounds more. Lincoln 6010 5p+ is my new favorite rod. I run at 90 amps, and am very pleased with my welds. I'm sure your are aware to. Once i start the arc i can't. I'm surprised it will keep the 6010 lit, something i haven't even expected. One of the main problems that i am having is getting the first pass in straight. I use these with my lincoln invertec 275 and sa200. We ran into some problems. I'm surprised it will keep the 6010 lit, something i haven't even expected. That said, arc force would have been nice.but for the tig machine it is, your experience sounds more. One of the main problems that i am having is getting the first pass in straight. We ran into some problems. If i go up to 95, or even. The operating characteristics, mechanical properties, and welding applications of the 6011 resemble those of the 6010, but the 6011 requires alternating current. They don't work well on small portable engine driven welders. I'm sure your are aware to keep the rod basically pointed towards. One of the main problems that i am having is getting the first pass in straight. We ran into some problems. I am trying to learn horizontal fillet welds using 1/8 6010 electrodes. I'm surprised it will keep the 6010 lit, something i haven't even expected. Sorry if this has been posted before, but im having a problem with my 6010 electrode freezing everytime i try to do roots on butt welds, no matter if its vertical, horizontal,. Lincoln 6010 5p+ is my new favorite rod. I get the same results,. I run at 90 amps, and am very pleased with my welds. If i go up to 95, or even 100. I use these with my lincoln invertec 275 and sa200. Once i start the arc i can't. Ive been practicing vertical up fillets with 3/32 7018.Guidelines smaw

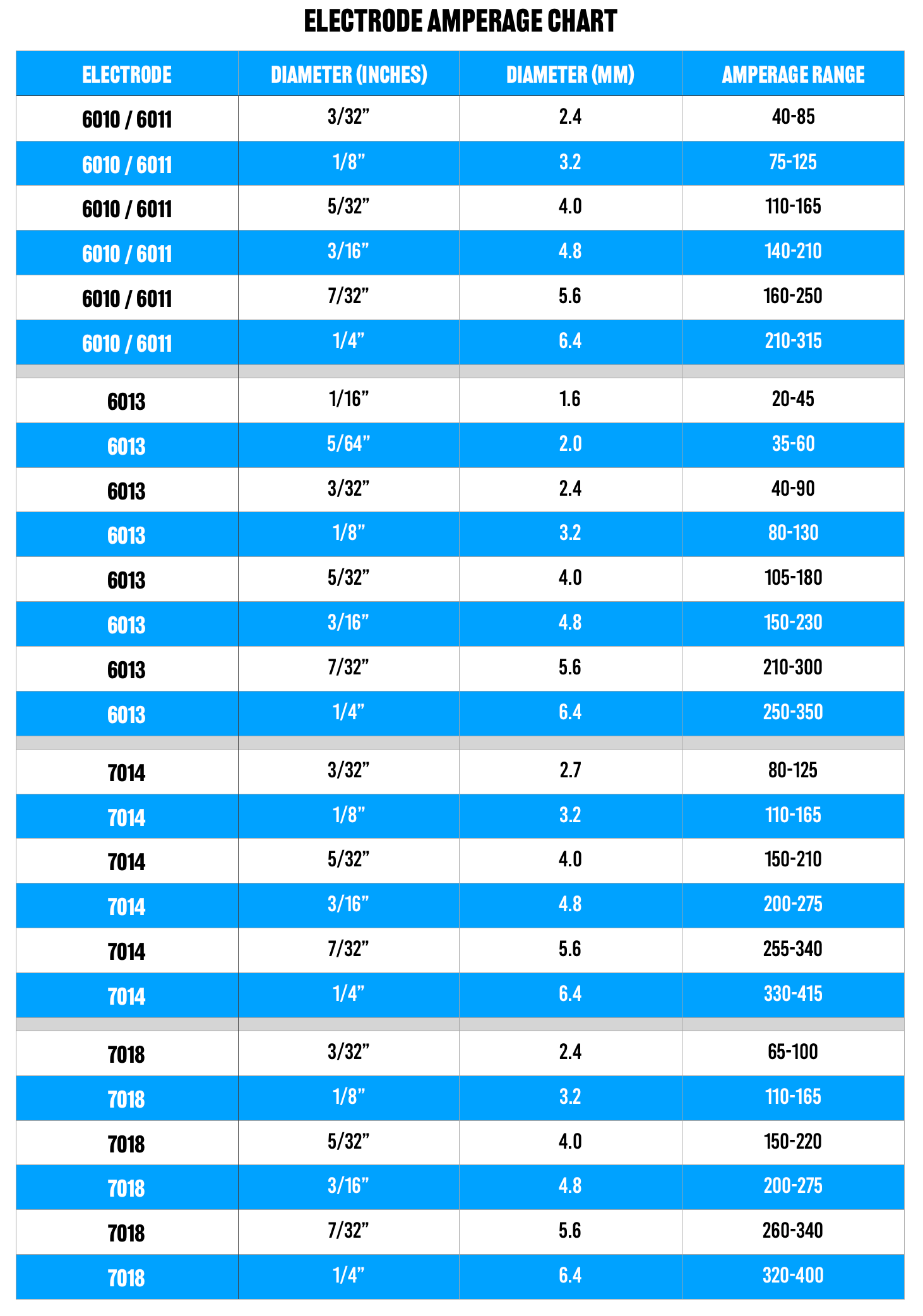

Electrode Amperage Chart Baker's Gas & Welding Supplies, Inc.

6010 Electrode Amperage Chart Unbeatable Offers www.oceanproperty.co.th

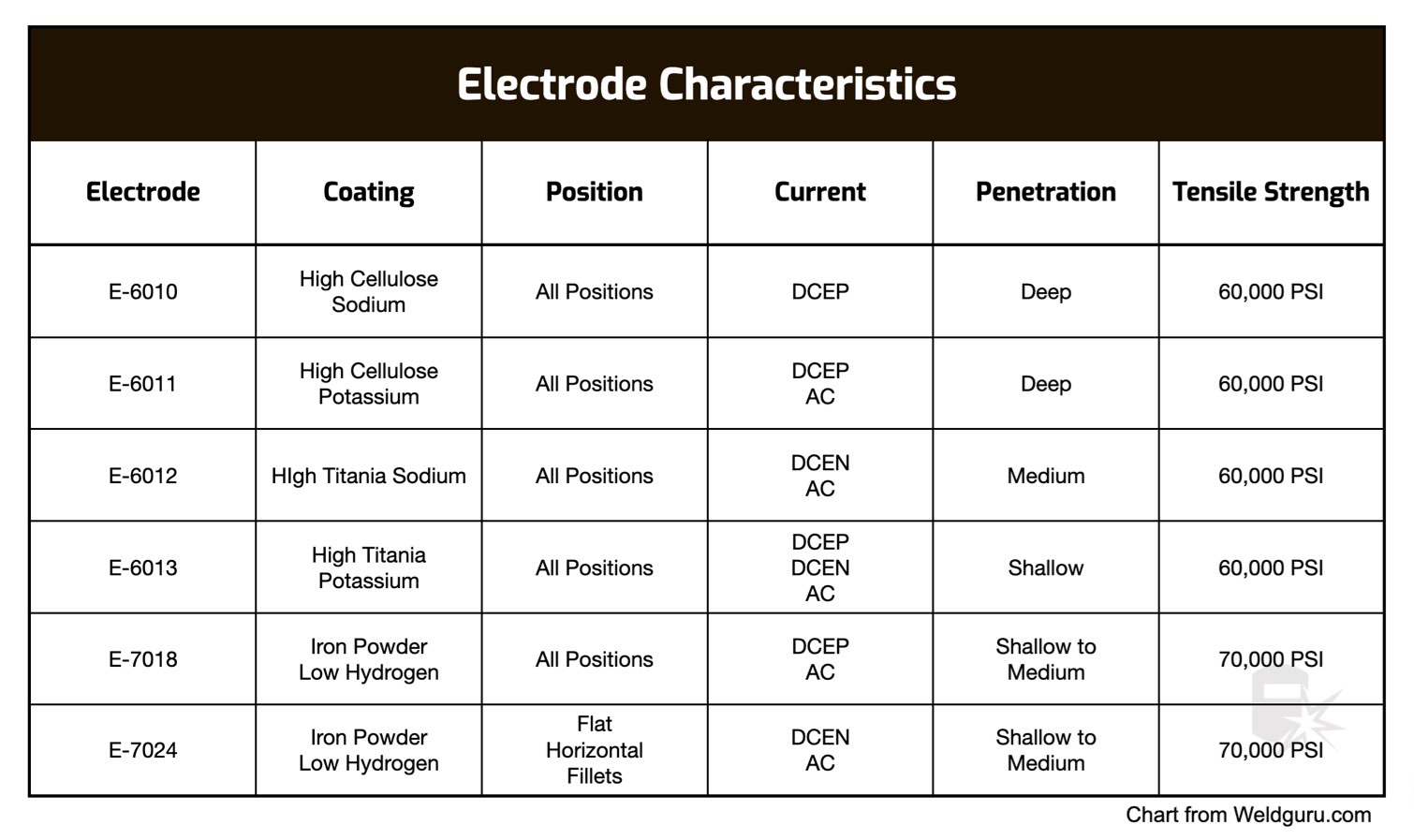

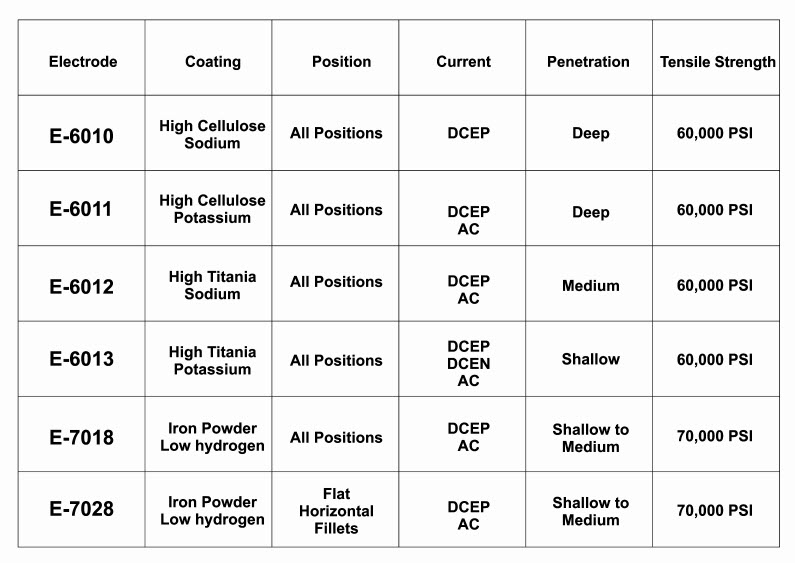

Welding Electrode Chart And Selection Weld Guru

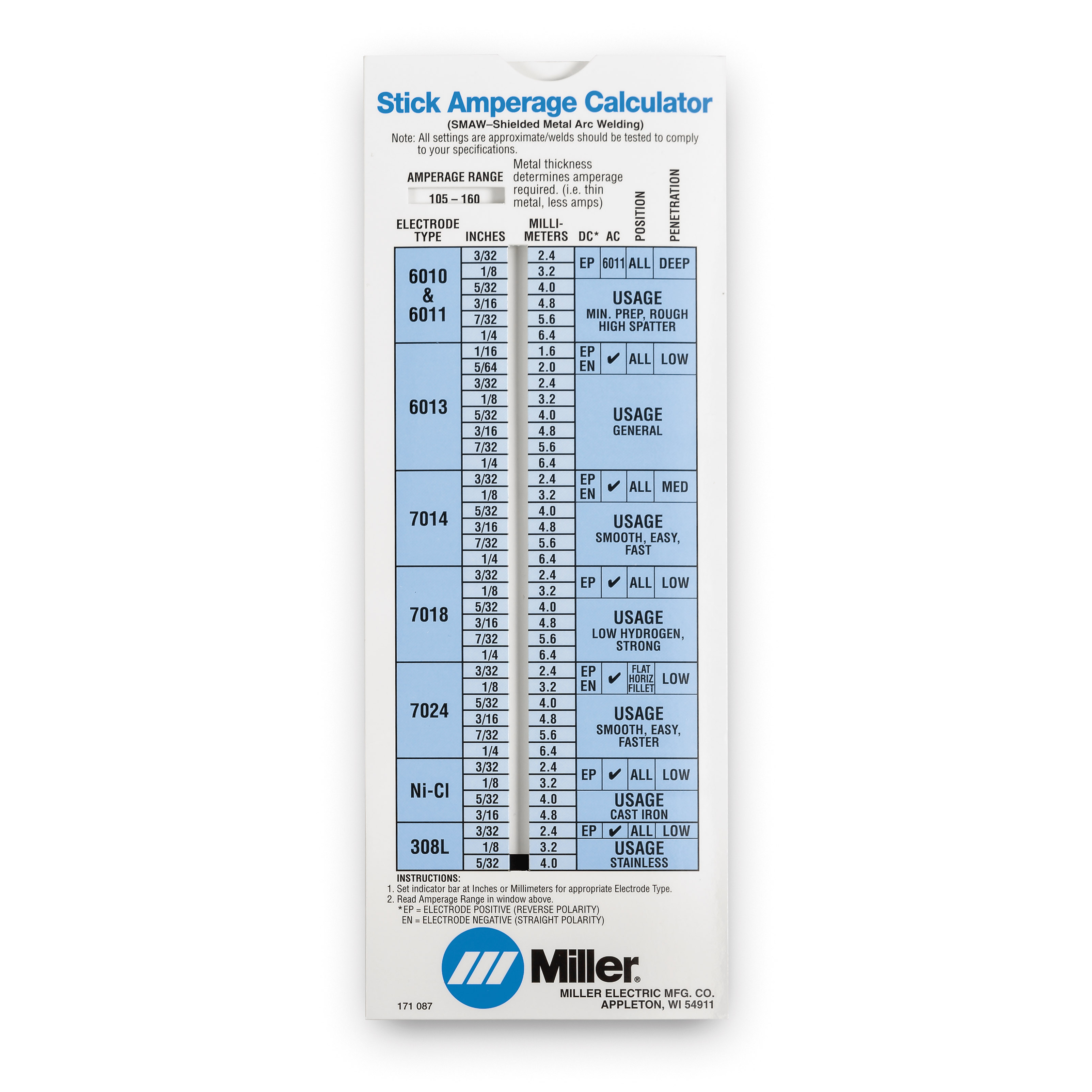

Welding Rod Amperage Chart at Darcy Ryan blog

Welding Electrode Chart and Selection Weld Guru

Weld Rod Size Amperage Metal Thickness Chart PDF

Arc Welding Rods Guide

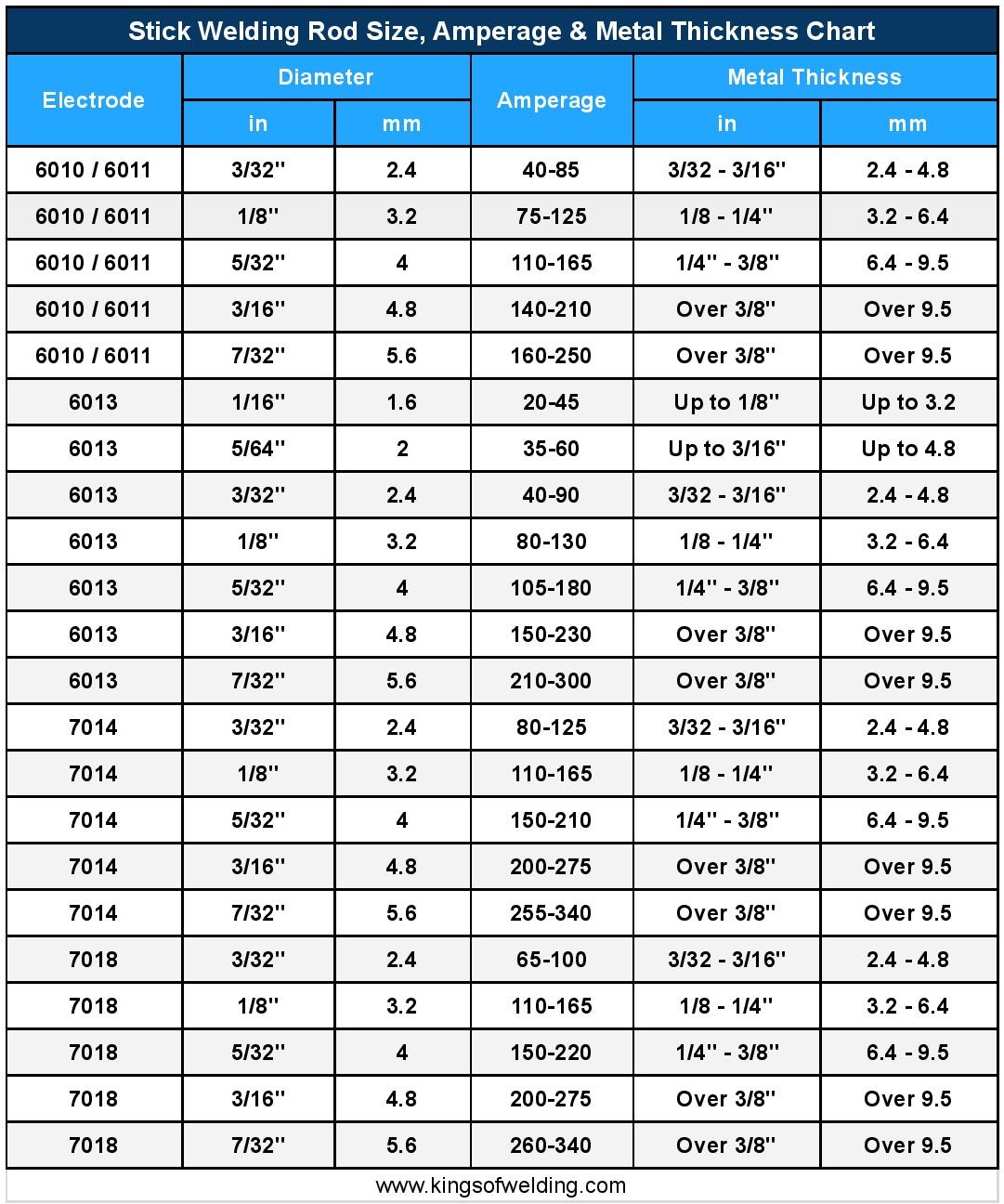

Welding Rod Sizes, Amperage & Metal Thickness Chart Kings of Welding

I Know The Test For 2 Xx Heavy Wall Is Different From 6 But For Me.

Being A Structural Hand, And Not Running A Lot Of 6010.

That Said, Arc Force Would Have Been Nice.but For The Tig Machine It Is, Your Experience Sounds More.

Also Should Be Used 1/8 Electrode.

Related Post: